0102030405

Current Status of Incinerator Technology Development

2024-03-31 11:39:44

1. What is an incinerator?

Traditional incinerators use high-temperature combustion to decompose incinerated garbage and other objects into charcoal, carbon, water vapor, carbon dioxide, nitrogen dioxide, sulfur dioxide, ozone, carbon monoxide, dioxins, and other solids that cannot be burned and decomposed. To reduce the space occupied by garbage and avoid the breeding of bacteria and odor. The incineration process can be divided into high-temperature mechanical grate incinerators, fluidized bed incinerators, and rotary kiln incinerators according to the incineration method. It is characterized by a large processing capacity and is suitable for the centralized treatment of municipal solid waste.

2. What is incinerator used for?

The waste generated in daily life is classified. Cartons, plastic bottles, metals, etc. can be recycled. Organic waste such as peels and leftovers can be composted and fermented. While reducing the amount, organic fertilizer substrate can be produced. For other waste that cannot be recycled, current common methods of disposal include landfilling and incineration. The function of the incinerator is to centrally incinerate the non-recyclable household waste, convert it into a small amount of ash and flue gas, and recover the heat generated during the incineration to generate electricity.

3. Which is better landfill or incineration?

When it comes to waste management, the debate between landfilling and incineration has been going on for many years. Both methods have their advantages and disadvantages, and choosing between the two can be a complex decision.

Landfilling is a traditional waste disposal method in which waste is buried in a designated area. The disadvantage is that it occupies a large area and produces methane, leachate and other products during the landfill process. Improper management may contaminate soil and water sources. Incineration, on the other hand, involves burning waste at high temperatures to reduce its volume and produce energy. However, incineration plants release pollutants such as dioxins and heavy metals into the air, posing potential health risks to nearby communities.

As technology advances, modern incinerators are equipped with advanced air pollution control systems to minimize emissions and use the heat generated during the incineration process to provide heat and power. Landfill operators are implementing measures such as liners and leachate collection systems to reduce the environmental impact of waste disposal. In addition, some landfills have been converted from burying original waste into ash after incineration, which increases land utilization and reduces the production of leachate.

Ultimately, the decision to landfill or incinerate depends on a variety of factors, including waste type, available technology, and local regulations. Both methods have their place in waste management, and a combination of the two may provide more sustainable solutions for the future.

4.HYHH’s latest waste incineration technology principle

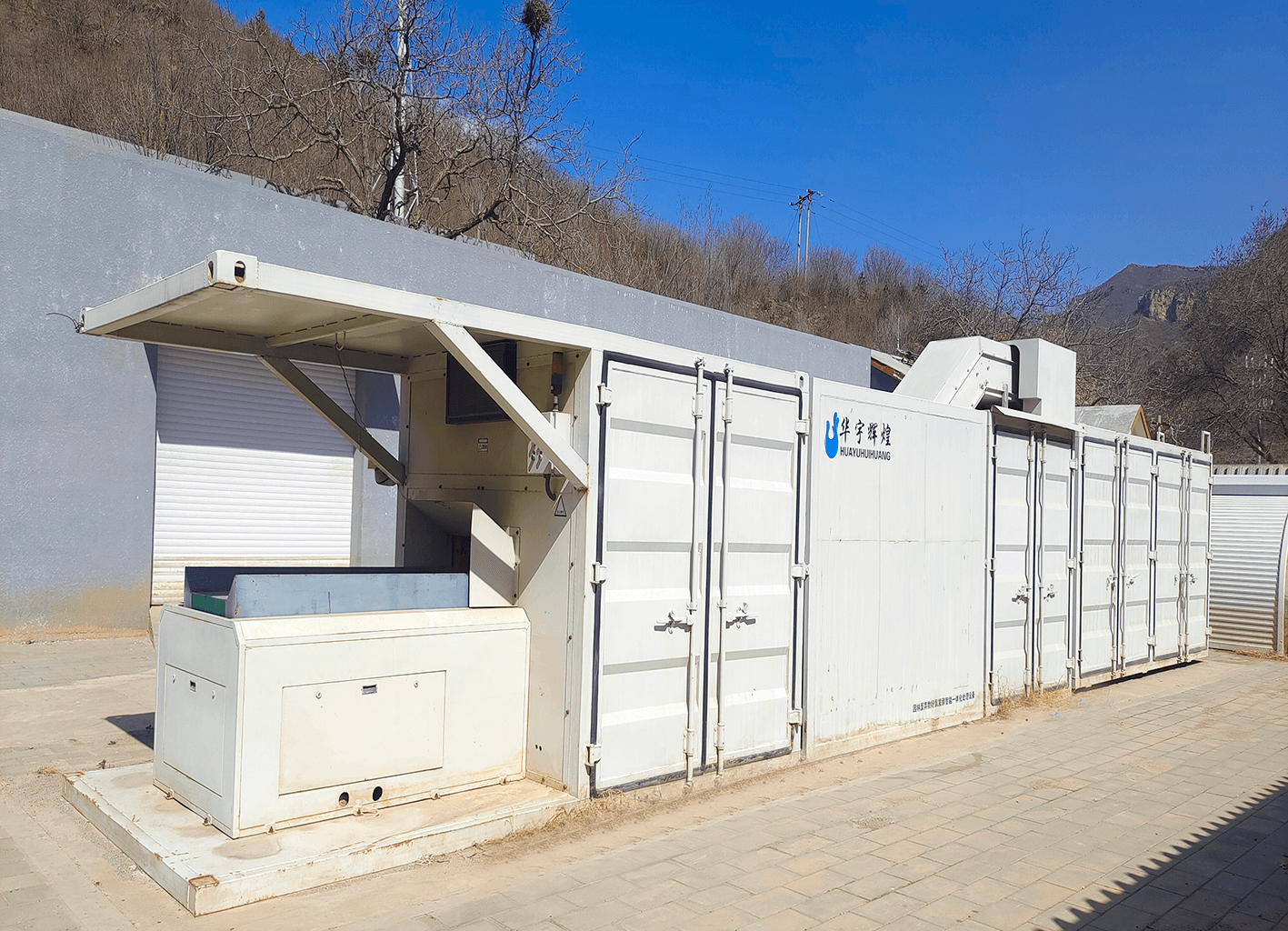

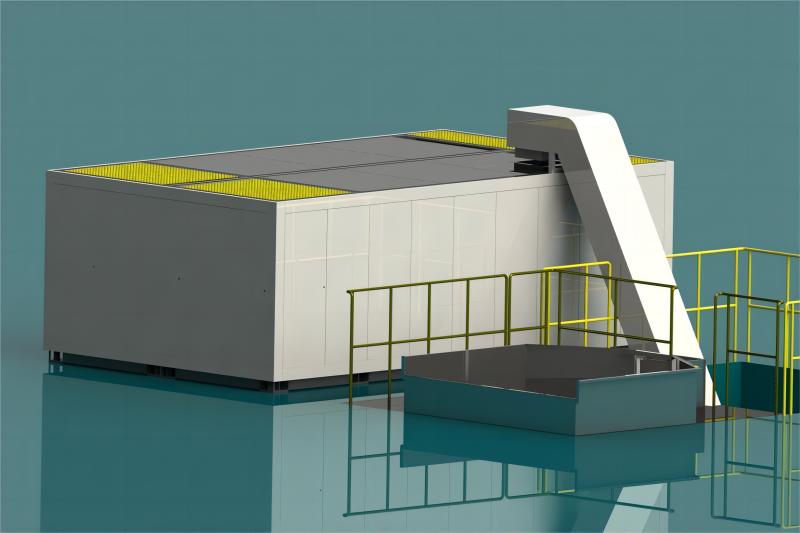

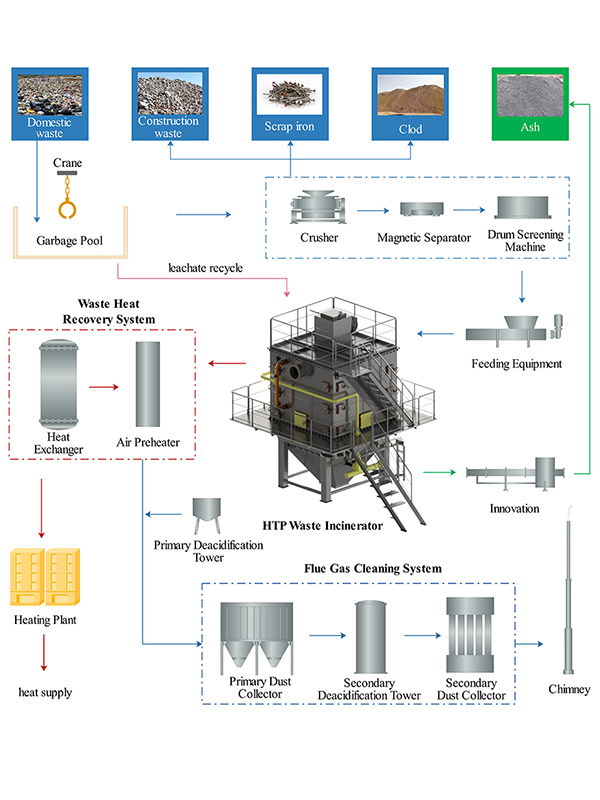

HYHH has developed on-site small-scale waste incinerators for remote areas where waste production is insufficient to build large-scale waste incineration plants. To achieve stable operation of the waste incinerator and meet flue gas emission standards, HYHH provides a supporting Waste Pyrolysis Gasification Treatment System, which mainly consists of four major systems: pretreatment system, HTP waste incinerator, the high temperature, waste heat recovery system and the flue gas treatment system.

The composition and functions of different systems are as follows:

①Pretreatment System, including crushers, magnetic separators, screening machines and other equipments to achieve the reduce the waste size and remove of metal, slag and sand.

②HTP Waste Incinerator, the pretreated domestic waste enters the pyrolysis gasifier, and mainly goes through two stages of low-oxygen pyrolysis and peroxygen combustion in the pyrolysis gasifier. The first stage is pyrolysis and gasification in a low-oxygen state, which is carried out in a combustion chamber at a working temperature of about 600~800°C to generate combustible gas and solid ash. In the second stage, the combustible gas enters the second combustion chamber from the first combustion chamber through the pores, and burns with oxygen in the second combustion chamber. The temperature is controlled at 850~1100°C, and is finally discharged into the waste heat recovery system. The solid ash gradually falls into the ash discharge chamber and is discharged through the slag discharge machine.

③The Waste Heat Recovery System includes equipment such as settling chambers, heat exchangers, and quenching towers. Its main function is to settle large particulate matter in the flue gas, recover the heat from the high temperature gas, rapidly cool down the flue gas, and avoid the regeneration of dioxin. For small scale system, the recovered waste heat usually in the form of hot water.

④The Flue Gas Treatment System, including dry powder injectors, fabric filter, acid-base spray towers, chimneys, etc., is mainly used to purify flue gas and ultimately achieve emission standards.

Welcome to leave a message for consultation!