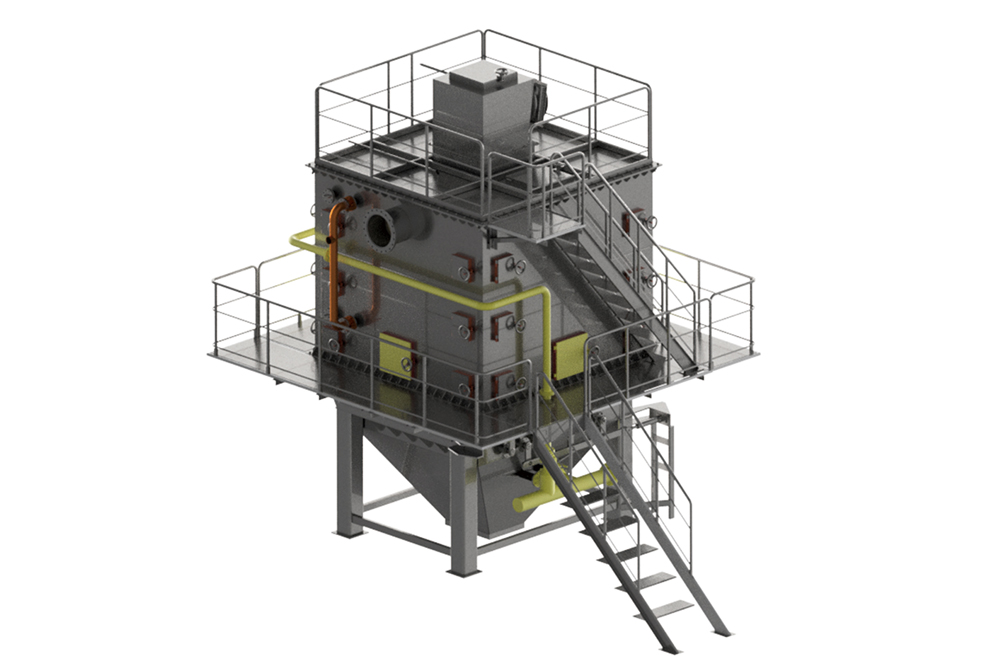

High Temperature Pyrolysis Waste Incinerator

Application Scope

Decentralized point source domestic waste treatment and reuse, such as towns,villages, islands, expressway service areas, infected areas, logistics concentration areas, construction sites.

General Waste Market Information

Waste accumulation is reaching threatening level worldwide. Today, with limited land resources, more and more shortcomings of landfill method are exposed dor example secondary pollution and higher costs. They are not an effective solution. Incinerators are facilities specifically designed for the treatment and disposal of general waste through high-temperature combustion. This process not only reduces the amount of waste, but also generates energy in the form of heat and electricity. As a result, incinerators have become an integral part of the general waste market, providing a viable solution for waste management and resource recovery.

On the other hand, the continuous optimization of incineration technology, resulting in fewer emissions and safer disposal methods, avoids all direct and indirect risks associated with other disposal methods. Small-scale decentralized waste incinerators can uniformly process waste at the location where waste is generated to avoid the risk of cross-contamination and keep waste treatment costs at an acceptable level.

HTP Waste Incinerator

HTP Waste Incinerator’s throughput between 3t and 20t per day, depending upon your requirements. Our HTP Waste Incinerator adopts a unique double combustion chamber structure, the inner lining is made of refractory castables, and the outer part is made of all-steel structure, which has excellent heat preservation ability, heat insulation, and corrosion resistance effects. There is no need to add fuel except in the starting part of the furnace to keep the temperature stable above 850°C, which is more green and environmentally friendly than other incinerators. There are various temperature, pressure and flow measurement points on the incinerator body, which can monitor the operation of the furnace in real time.

We are a professional manufacturer of multi-purpose incinerator technology with extensive experience in incinerator research and development, providing a flexible approach to solving your waste disposal problems. Our designers have the expertise to modify any incinerator to suit your business needs and can even design a completely custom operating system based on your business standards.

Product Parameter

No. |

Model |

Service life (a) |

Capacity(t) |

Weight (t) |

Gross power (kW) |

Area of equipment (m2) |

Area of the factory (m2) |

1 |

HTP-3 t |

10 |

≥ 990 |

30 |

50 |

100 |

250 |

2 |

HTP-5 t |

10 |

≥ 1650 |

45 |

85 |

170 |

300 |

3 |

HTP-10 t |

10 |

≥ 3300 |

50 |

135 |

200 |

500 |

4 |

HTP-15 t |

10 |

≥ 4950 |

65 |

158 |

300 |

750 |

5 |

HTP-20 t |

10 |

≥ 6600 |

70 |

186 |

350 |

850 |

Note: Other models can be negotiated and customized according to customer needs.

Process Flow

Environmental Standards

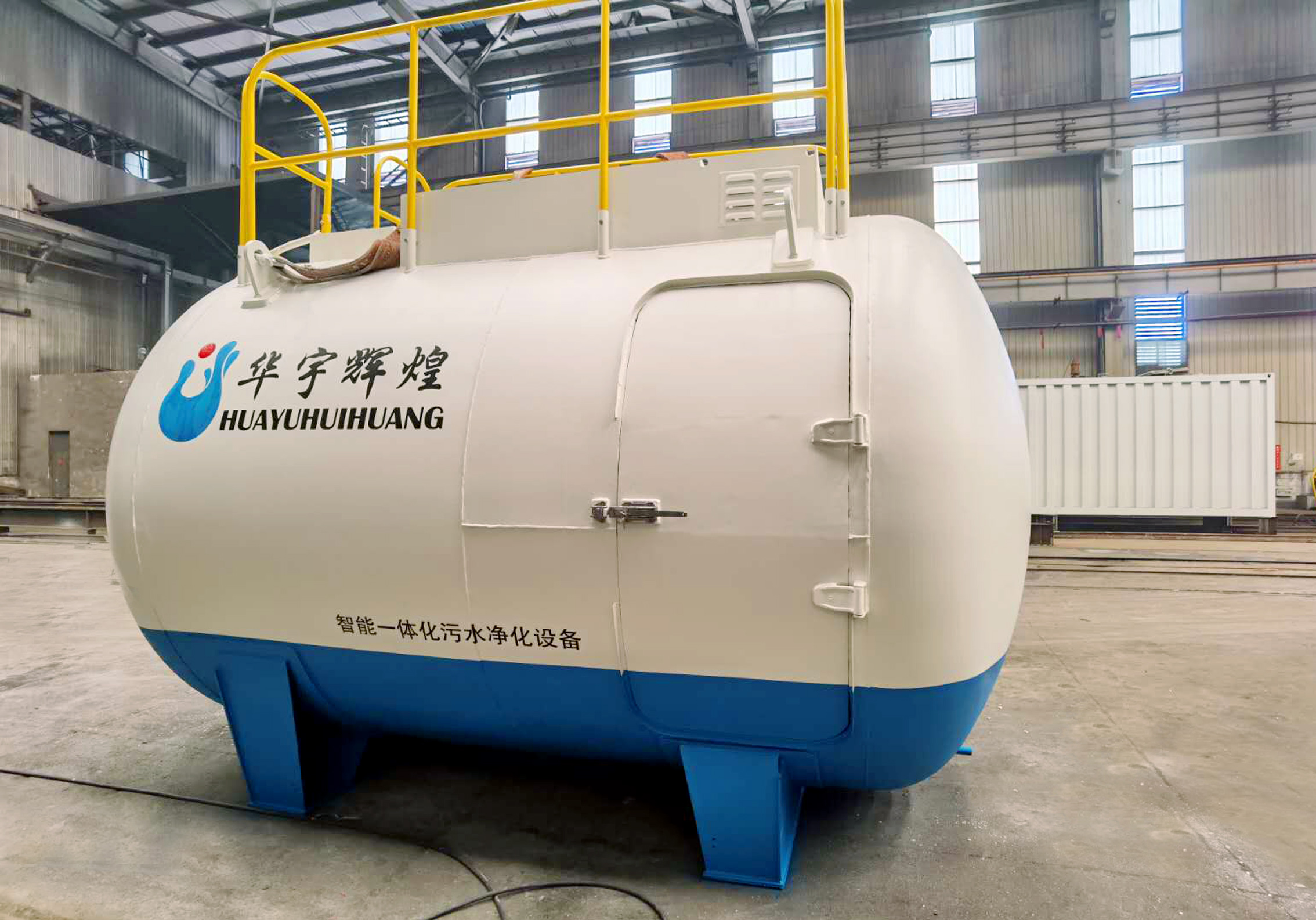

Waste Water The leachate and a little amount of process wastewater are returned to the furnace for incineration and discharged with flue gas.

Exhaust Gas The treated exhaust gas meets local standards of pollutant discharge.

Waste Slag The waste slag meets local standards of pollutant discharge and and it can be used for landfill or paving.

Key Technologies

Technology+Structure + Control

HYHH is committed to serve the environmental protection, and root in continued innovation in products and technologies.

01 Rapid pyrolysis total gasification technology

02 Improved oxygen supply control technology

03 Low nitrate reaction technology

04 Homogeneous combustion technology

05 Waste heat utilization technology

06 Combined flue gas ultra-clean technology

07 Fully closed reaction technology

08 Intelligent control technology

HTP Waste Incinerator has obtained 5 invention patents and 6 utility model patents.

Five Technical Features

① Good inclusiveness

Aiming at the characteristics of small output, complex composition and large fluctuation of domestic waste in countyside, solving the problem of small-sacle domestic waste treatment in the whole process. Through the links of standing, crushing, magnetic separation and screening, the garbage is homogenized to ensure the stability of the garbage into the furnace. Can be applied to a variety of materials : such as rubber and plastic, paper, knitting, plastic, etc.

② Low operation cost

HTP Waste Incinerator is an integrated design with double-chamber that effectively increases the heat storage capacity. Hot air from the waste heat recovery is used to supply hot oxygen in the post-combustion chamber for fuel-free operation. The reaction process has low nitrate, no denitrification treatment, and reduced operation and construction costs. Operating costs are lower than other similar products.

③ Excellent treatment effect

The incinerator’s volume reduction rate of the waste can reach more than 95%, and has a mass reduction rate over 90%.

④ Eco-friendly

There is no odor leakage in the fully-closed micro-negative pressure state of the unloading workshop. The collected leachate is sprayed back into the incinerator to achieve “zero” discharge of wastewater. Two stages of deacidification and dust removal achieve ultra-clean emission of flue gas. Flue gas emissions are in line with local standards. The generated hot water can be used for heating to achieve resource utilization.

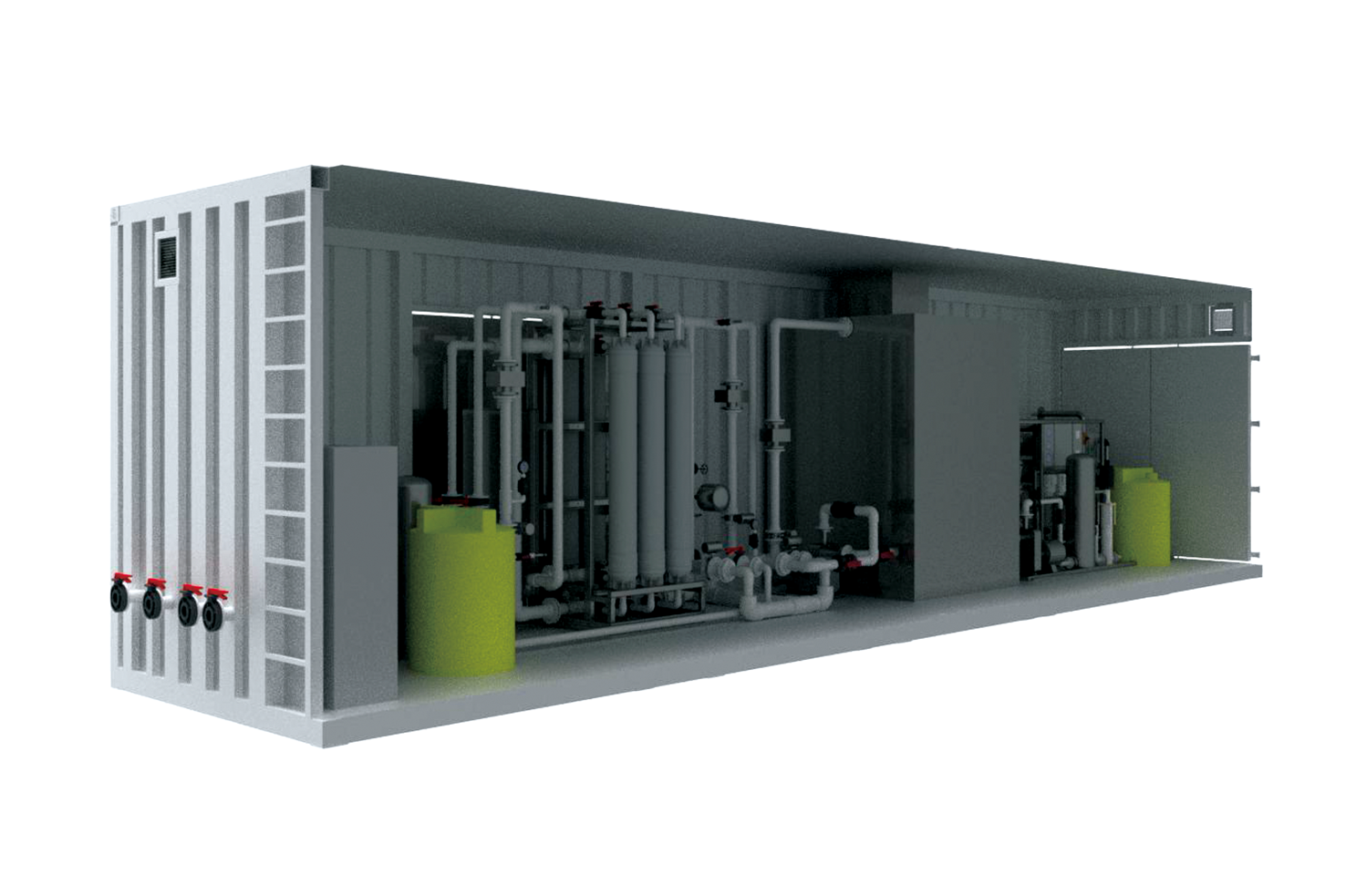

⑤ Intelligent automation

The central control room enables the start-up and stop of most devices, automatic water replenishment and dosing of devices. It is equipped with a variety of online instruments such as temperature, pressure and oxygen content to monitor the operational status of the system in real time.