Organic Waste Converter-Food Waste Bio-Digester

Equipment Features

①High-temperature Fermentation: Fermentation can reach 70℃, sterilization effectively and achieve harmlessness.

②High Degree of Reduction Rate: The equipment has high treatment efficiency, it can achieve a reduction rate of 10% of solid emissions.

③Eco-friendly: The output is an organic fertilizer matrix; non-toxic, harmless, eco-friendly, and resource-based.

④Modular Design: Flexible equipment combinations allow for large-scale centralized treatment to be performed lumped as well as scattered in-situ treatment.

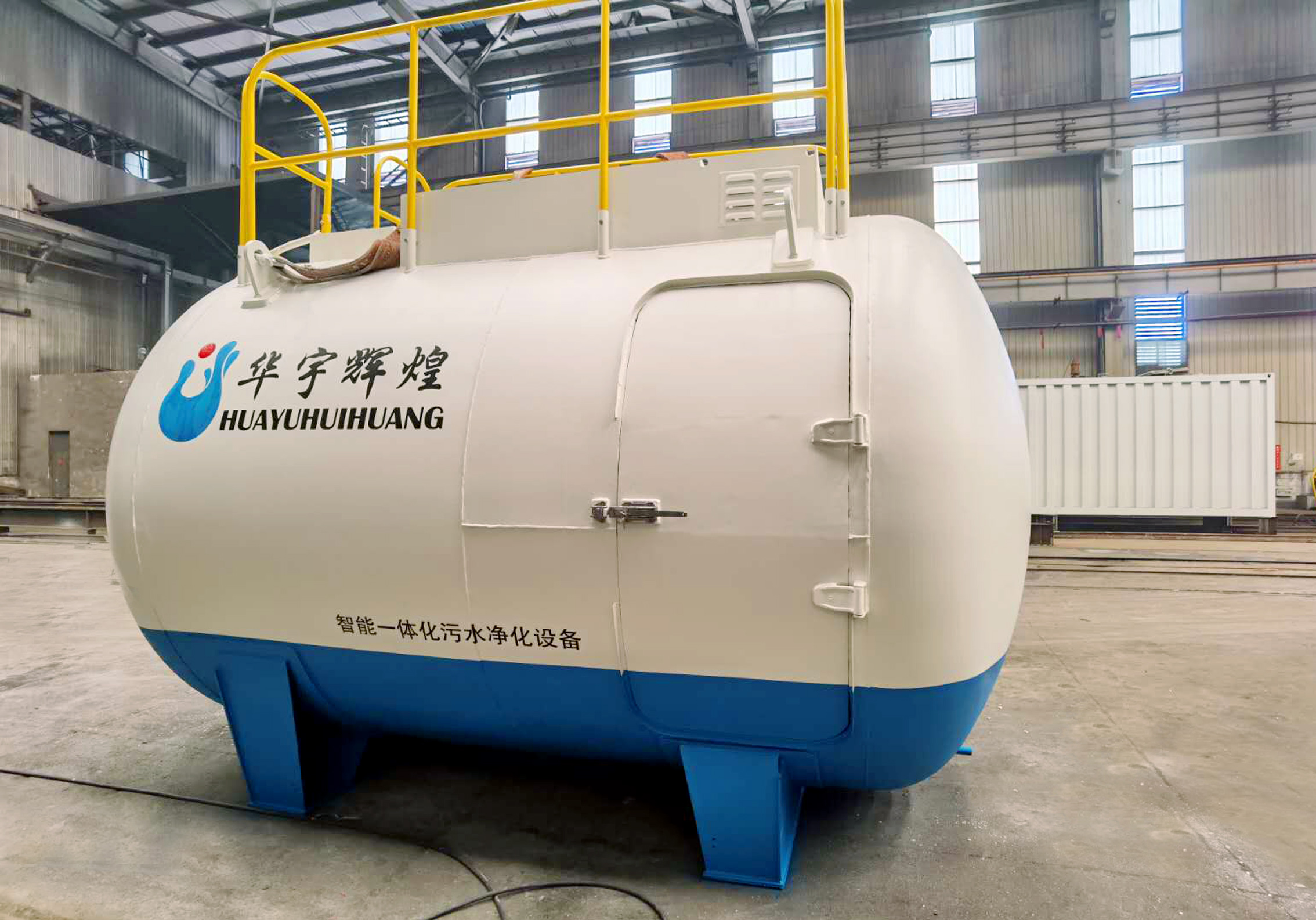

OWC Bio-Digester

OWC Bio-Digester is a series of organic waste converters that can consume 0.5-15t of food waste per day and convert it into high-quality organic fertilizer substrate. This process greatly preserves nutrients, preventing them from being lost through decomposition and decay of food waste in bins or landfills, reducing the risk of environmental contamination caused by improper disposal. OWC Bio-Digester has huge economic benefits and wide-ranging environmental benefits, which will save the planet at the same time!

The OWC Bio-Digester series has 6 standard models, and can also be customized according to your requirements. We have abundant R&D experience and provide complete after-sales service. Welcome to contact us for detailed information.

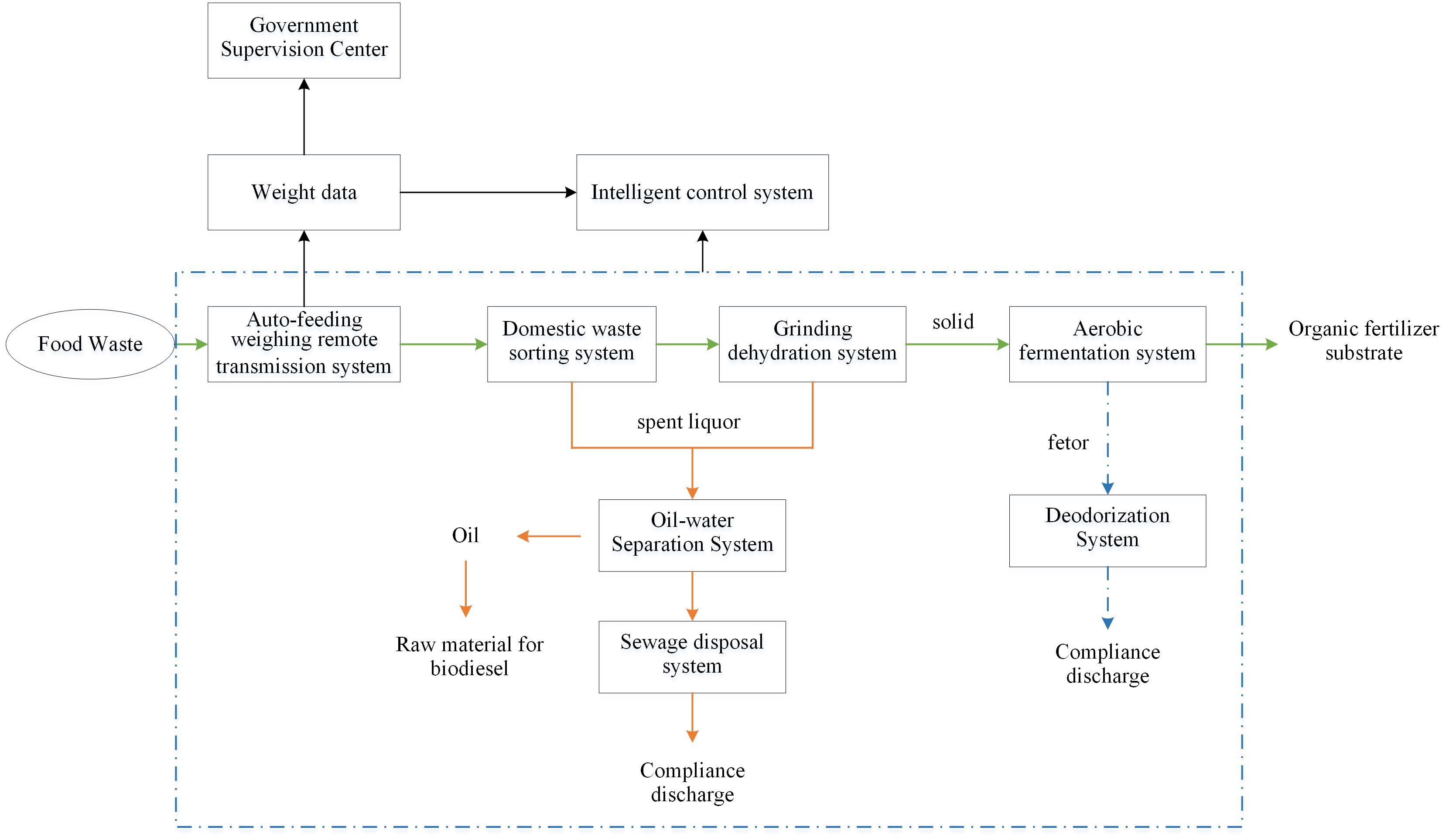

Process Flow

After the food waste is collected and transported in a centralized manner, it enters the automatic feeding and sorting system to complete classification preprocessing. The screw dehydration system crushes the sorted food waste and performs preliminary solid-liquid separation.

The solid discharge enters the aerobic fermentation system for high-temperature aerobic fermentation. The final product is used as organic fertilizer raw material. The liquid enters the oil-water separation system for oil separation treatment, and then discharged to the municipal pipe network. The waste gas generated by the pretreatment system and high-temperature aerobic fermentation system then enters the deodorization system, emiss treated waste gas that meets local standards.

The entire processing process is automatically controlled through the intelligent control system, and the equipment operates automatically.

Product Specifications

| Model |

Scale (t/d) |

Area of equipment (m2) |

Installed power (kW) |

Population service (per) |

Resource rate (%) |

Service life (a) |

OWC-0.5T |

0.5 |

60 |

24 |

> 1250 |

90 |

10 |

OWC-1T |

1 |

100 |

28 |

> 2500 |

90 |

10 |

OWC-3T |

3 |

250 |

56 |

> 7500 |

90 |

10 |

OWC-5T |

5 |

300 |

90 |

> 12500 |

90 |

10 |

OWC-10T |

10 |

480 |

210 |

> 25000 |

90 |

10 |

OWC-15T |

15 |

600 |

270 |

> 37500 |

90 |

10 |

Environmental Standards

Waste Water Sewage is discharged into the municipal sewage pipe network; if there is no municipal sewage pipe network, it can be collected and transported to the urban sewage treatment plant.

Exhaust Gas The treated exhaust gas meets local standards of pollutant emission.

Organic Fertilizer Each index meets the relevant standards of local organic fertilizer and can be sold as organic fertilizer.