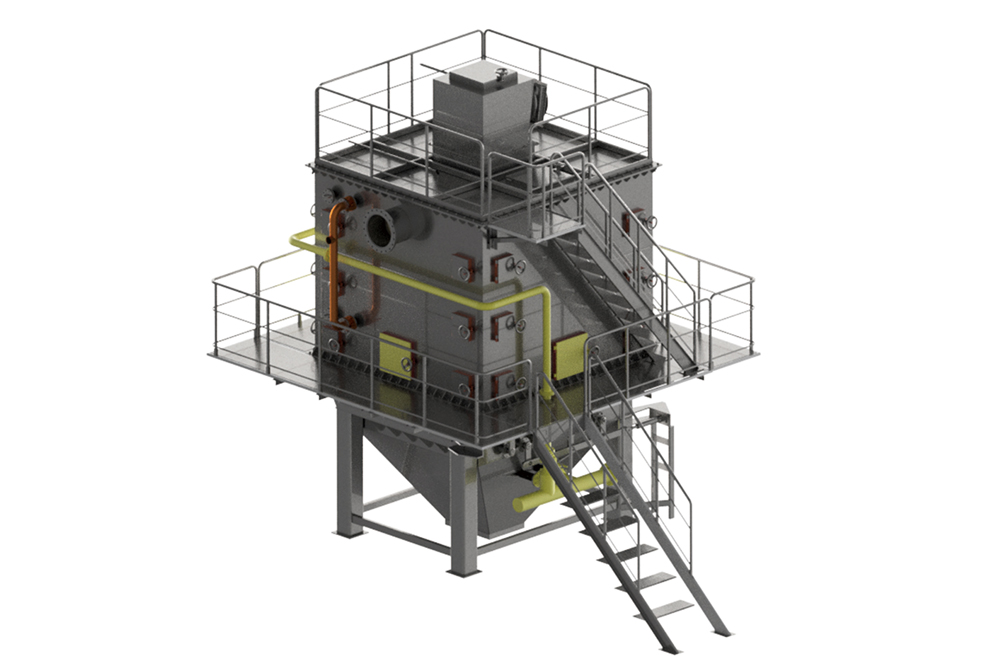

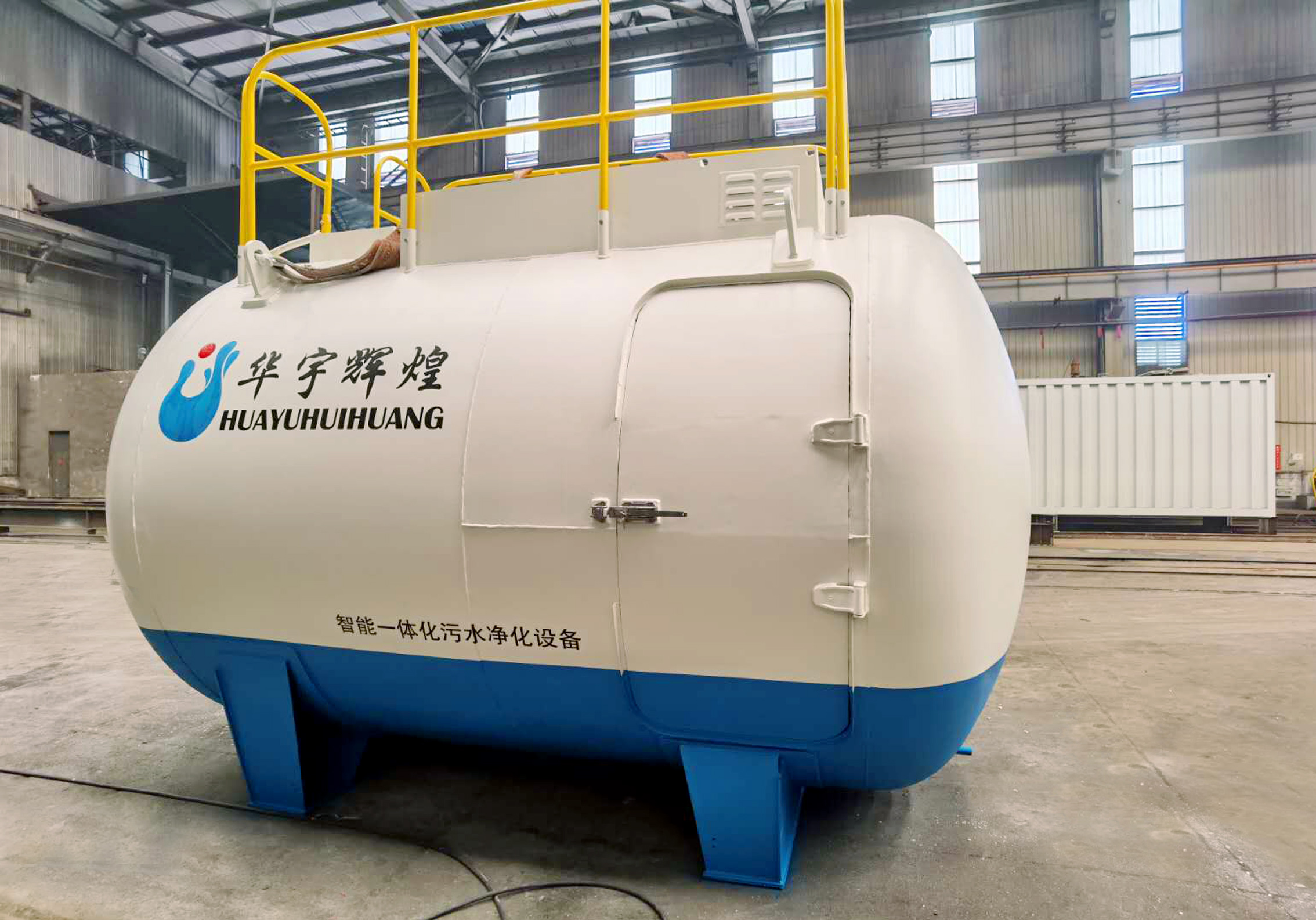

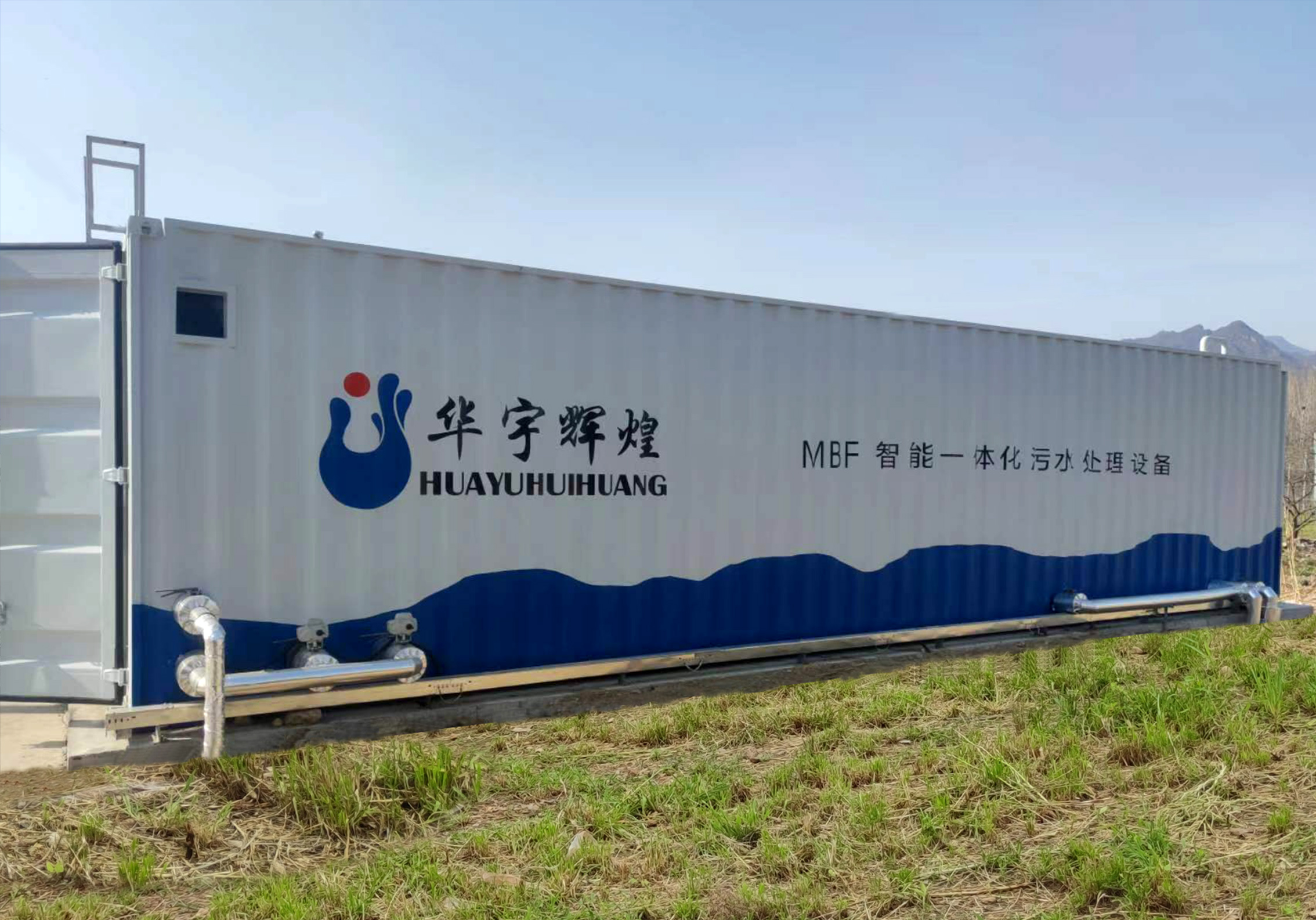

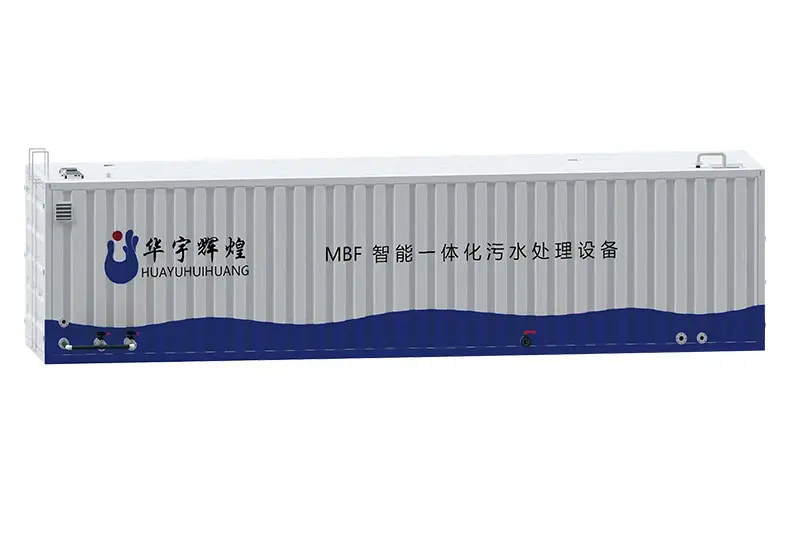

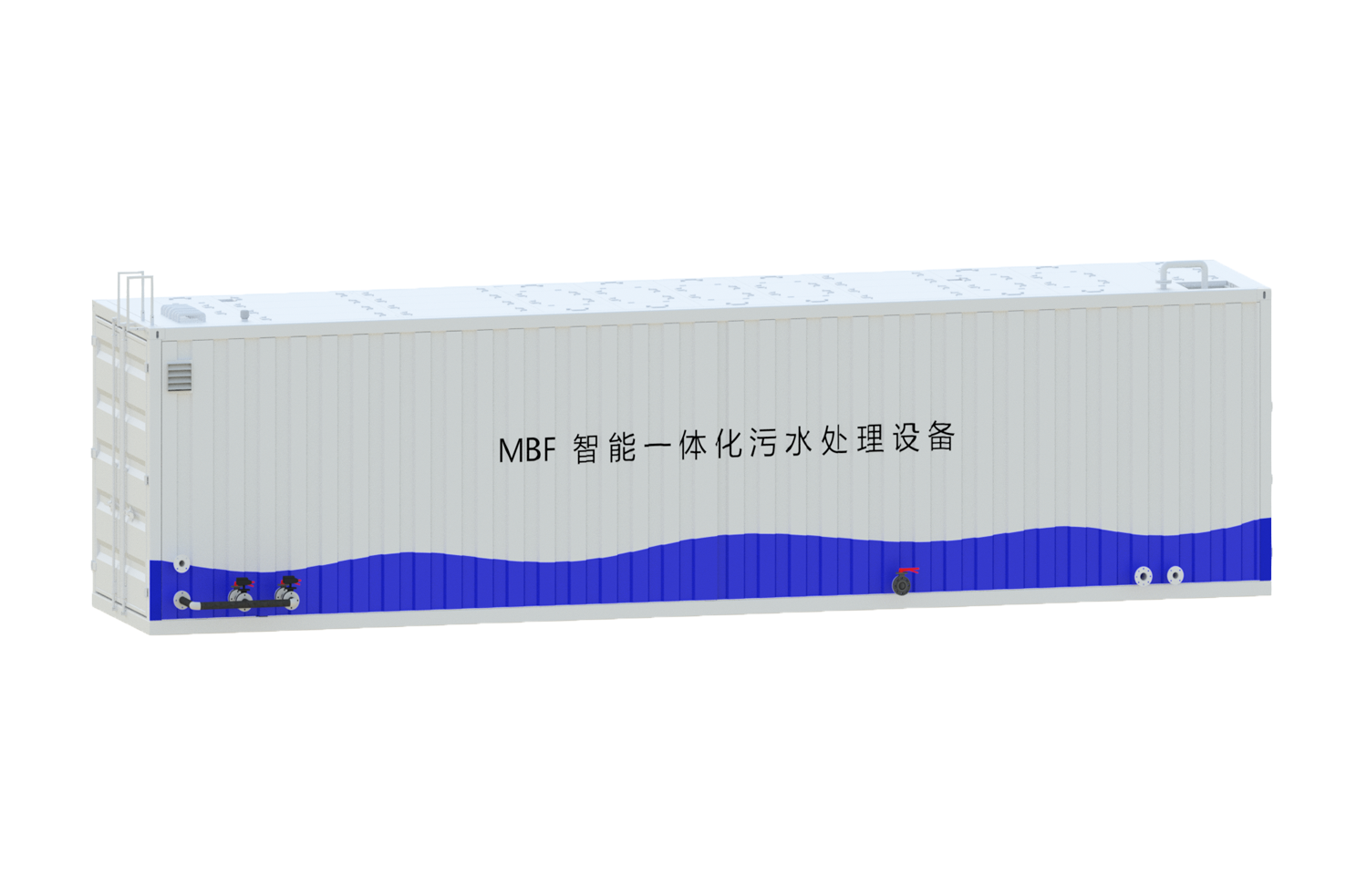

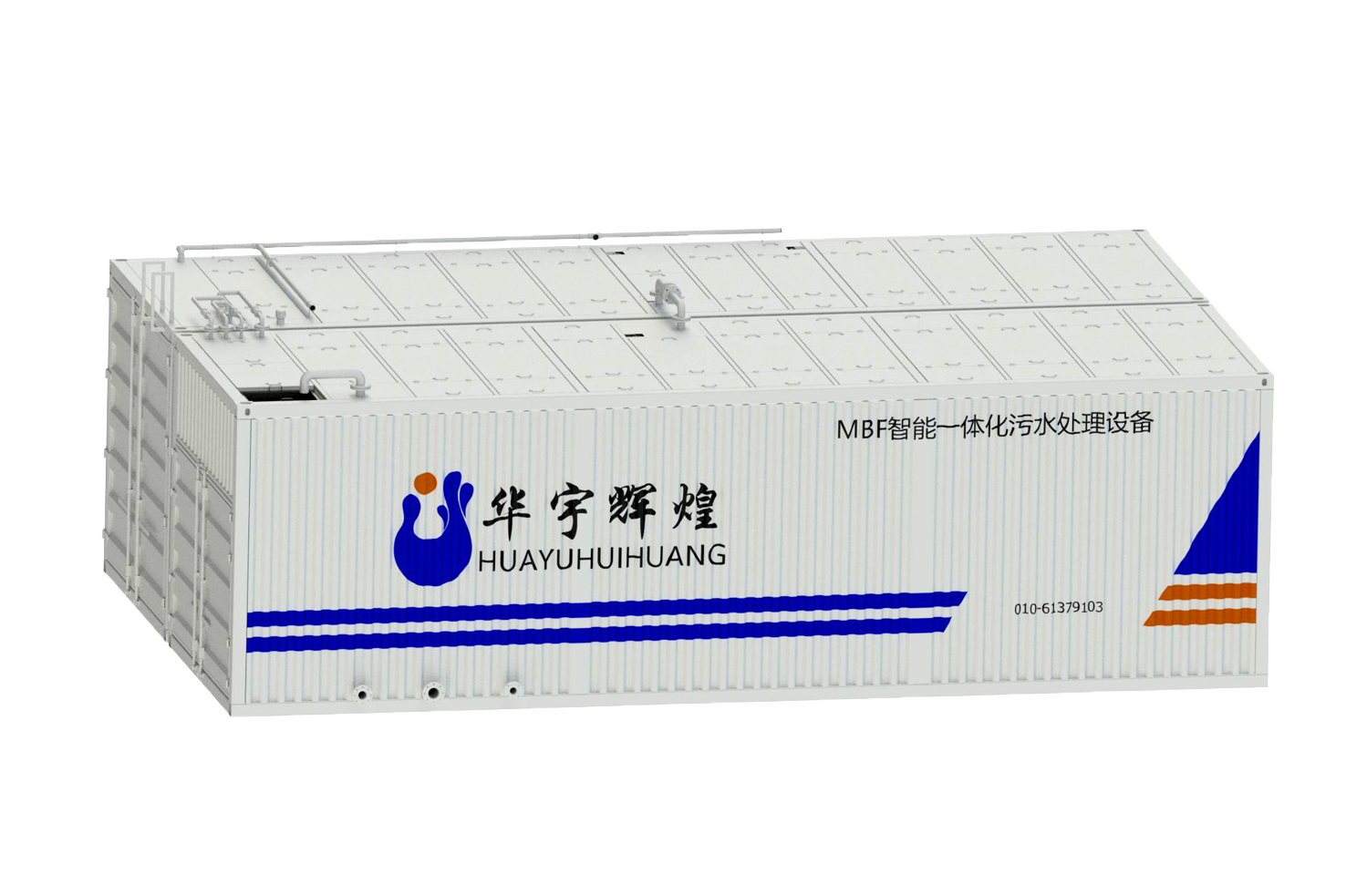

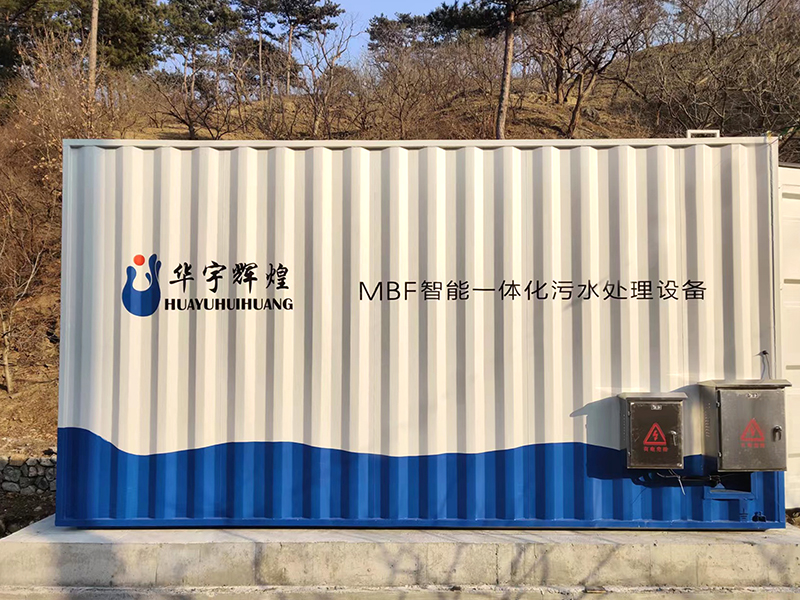

MBF Packaged Wastewater Treatment Reactor

Application Scope

①Decentralized rural sewage treatment in townships.

②Living sewage treatment in scenic spots, schools, hotels and hostels without municipal pipeline network.

③High-speed service areas, distant villa areas, sanatoriums, military camps, schools and hotels, etc.

④Point source interception along rivers and black smelly water bodies.

⑤Industrial or other sewage with the same target pollutant equivalent.

Equipment Features

①Eco-friendly

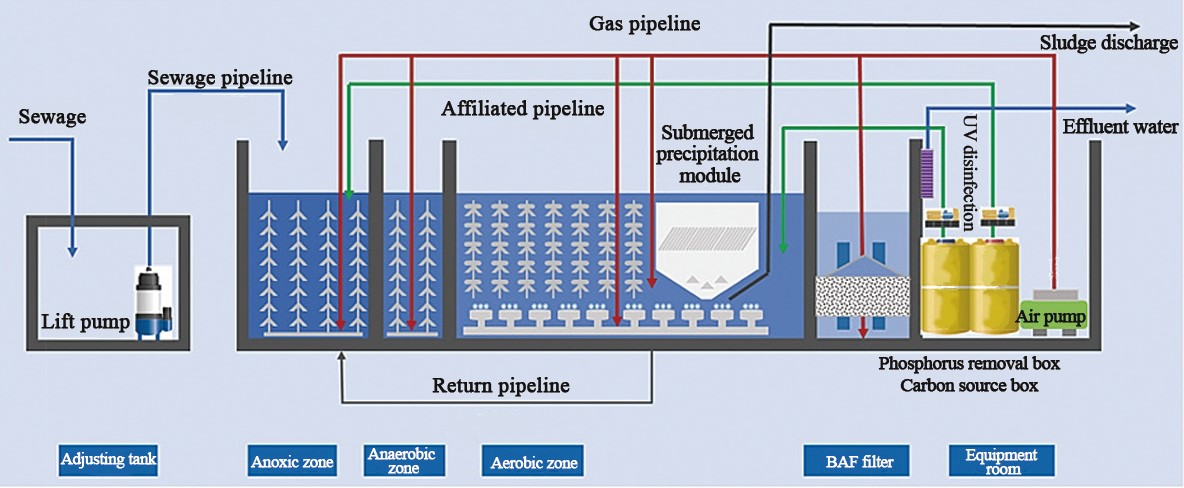

Anoxic zone and anaerobic zone are inverted to strengthen nitrogen removal and improve space efficiency.

②High treatment efficiency

Fixed-bed fiber bundle lanyard filler inside the biochemical zone to enrich more microorganisms and improve wastewater treatment efficiency.

③Energy conservation

Using cyclone mixer instead of traditional mixer to enable a more environmental friendly and energy saving function..

④Stable Operation

The innovative development of the "submerged precipitation module", which is built into the aerobic zone. Compared with the traditional process, no membrane washing systems is needed.

the membrane washing system is removed and the space utilization is improved, making the system operation more energy-saving and efficient. It improves space utilization and makes the system run more energy-efficiently.

Process Flow

Product Advantages

Autonomous Patents (MBF Packaged Bio-Reactor has 3 invention patents and 6 utility model patents).

"Submerged precipitation module" has reached the international advanced level.

Endorsed by China high-tech industry research association: MBF Packaged Bio-reactor is domastically and internationally advanced.

01 High biochemical efficiency

Adopting the inverted A2O activated sludge process to strengthen the biological denitrification and phosphorus removal effect. The biochemical area adopts fiber bundle lanyard filler to enrich biofilm and strengthen nitrification reaction.

02 Stable effluent to meet the standard

The effluent meets the relevant local discharge standards. The BAF filter ensures the stability of the effluent SS and the auxiliary dosing device to ensure the TP and TN meet the standard.

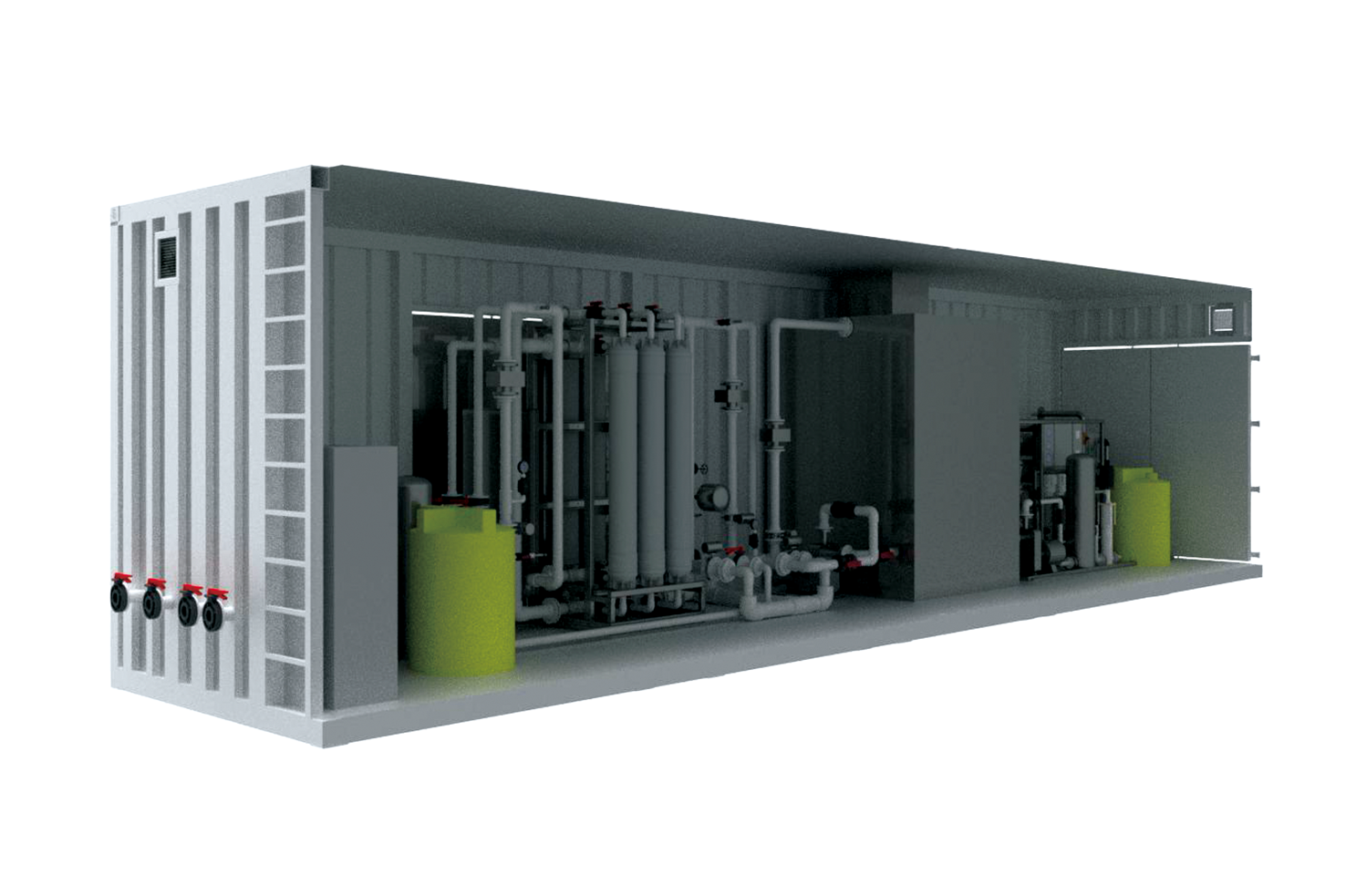

03 Easy to operate and maintain

Valves, pumps, fans, etc. are concentrated in the equipment room, which is safe and convenient for operation and maintenance. The dosing room is set up separately to increase the space for future equipment inspection and maintenance.

04 Automation, information technology

Realization of electrical PLC automation control:Access to water quality online analysis and cloud platform for remote equipment management and maintenance.

05 Energy saving and consumption reduction

Using the same blower to realize functions of oxygenation, agitation, irrigation and reflux. Biological phosphorus removal is the main process, chemical phosphorus removal is supplementary, saving pharmaceuticals.

06 Unique structure design

Integrated design using corrugated containers with high structural strength. The submerged precipitation module is built into the biochemical zone, with stable mixed liquid flow, good sludge properties and excellent settling performance.

07 Low investment and operating costs

Compact equipment integration, small footprint and cost efficient. Less power equipment, low installed power and low running cost.

08 Total Quality Control Certification

Realize the whole process of quality control from design, production, logistics, installation to commission and running.

Product Specifications

Model |

Scale (m3/d) |

Dimension L×W×H(m) |

Submerged Precipitation Module (pcs) |

Net Weight (tons) |

Installed Power (kW) |

Operating Power (kW) |

MBF-10 |

10 |

3.9×2.0×3.0 |

1 |

3.5 |

2.1 |

1.35 |

MBF-20 |

20 |

5.4×2.0×3.0 |

1 |

4.5 |

3.5 |

2.0 |

MBF-30 |

30 |

6.4×2.0×3.0 |

1 |

5.5 |

3.5 |

2.0 |

MBF-50 |

50 |

7.5×2.5×3.0 |

1 |

7 |

3.7 |

2.2 |

MBF-100 |

100 |

13.0×2.5×3.0 |

2 |

11.3 |

6.1 |

4.6 |

MBF-120 |

120 |

13.0×3.0×3.1 |

2 |

11.5 |

6.2 |

4.7 |

MBF-150 |

150 |

9.3×2.5×3.0*2pcs |

3 |

15 |

6.2 |

4.7 |

MBF-200 |

200 |

10.1×3.0×3.0*2pcs |

4 |

19 |

7.1 |

5.6 |

MBF-250 |

250 |

12.5×3.0×3.0*2pcs |

5 |

23 |

7.4 |

5.9 |

MBF-300 |

300 |

14×3.0×3.0*2pcs |

6 |

30 |

7.7 |

6.2 |

Cost

No. |

Indicators |

MBF series |

1 |

Land area per unit cubic meter water (m2/m3) |

0.13~0.4 |

2 |

Power consumption per cubic meter water |

0.3~0.5 |