DW Containerized Water Purification Machine

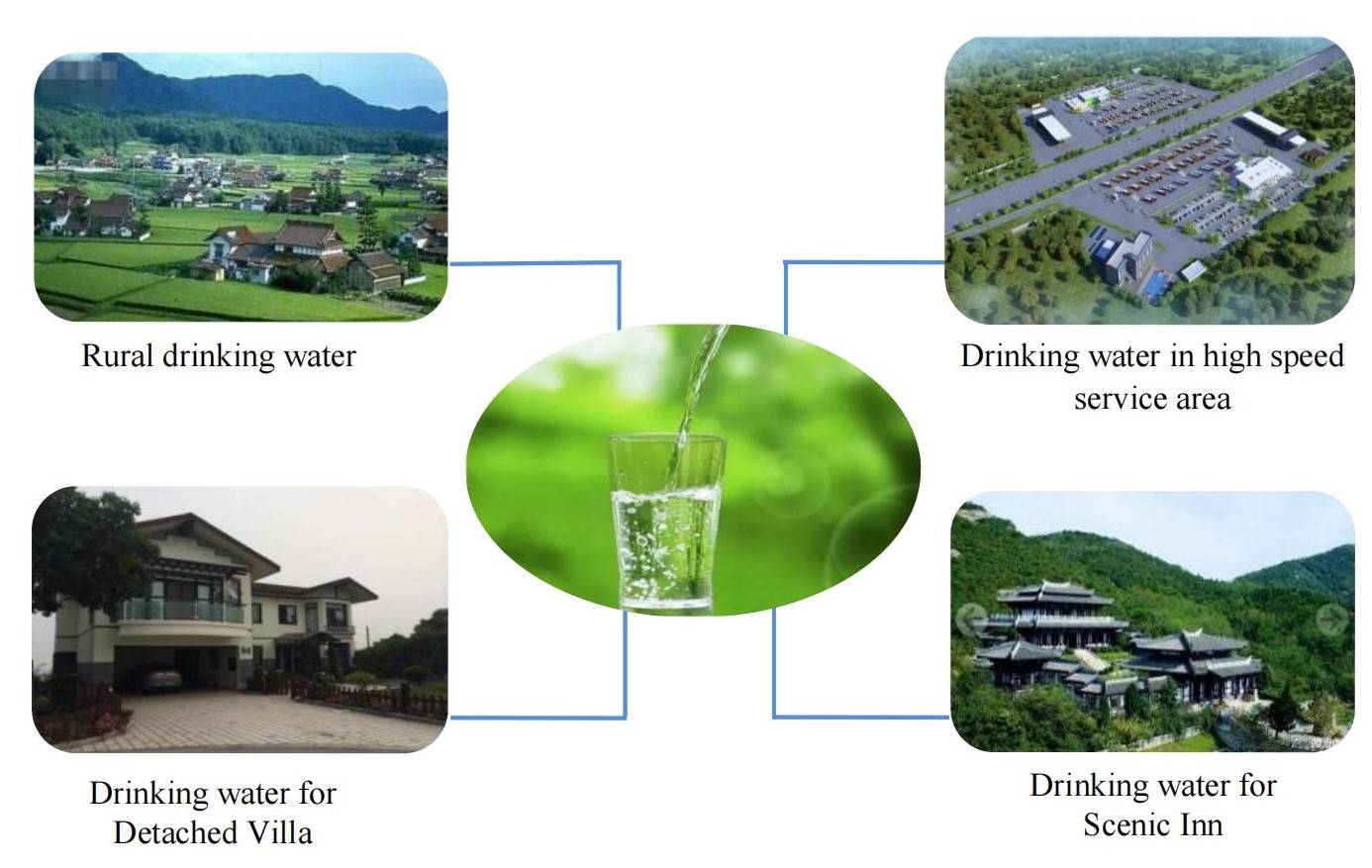

Application Scope

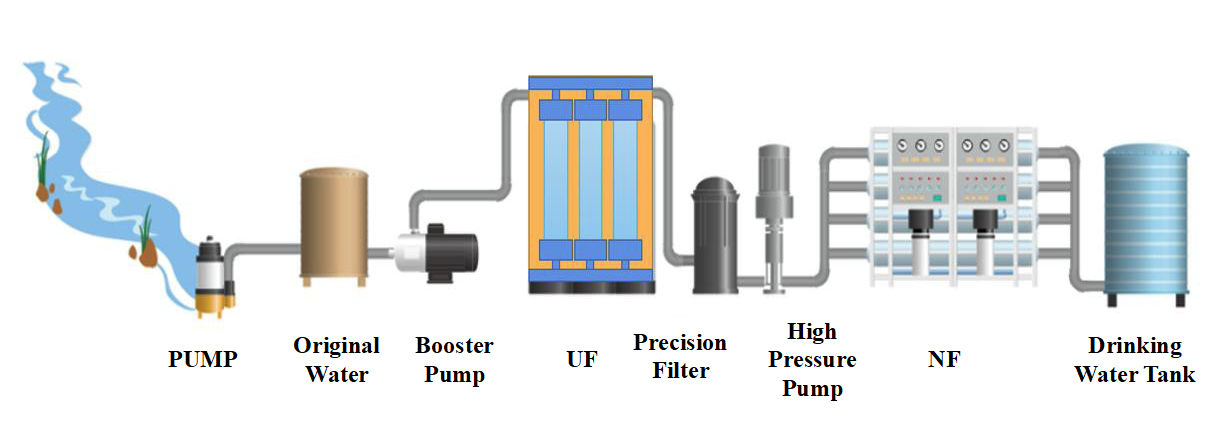

Process Flow

Application of ultrafiltration technology can effectively remove suspended matter, colloidal particles and bacteria, viruses, cryptosporidium, etc. from water. Flux design: less than 40 L/m²·h Output turbidity: less than 0.1 NTU Recovery rate: >90%

Nanofiltration technology can effectively remove heavy metals such as nitrate, sulfate, arsenic, calcium, magnesium and organic carcinogens from water, while retaining minerals and the right amount of trace elements in the water Flux design: less than 18 L/m²·h Desalination rate: >90% Recovery rate: 50-75%

Equipment Features

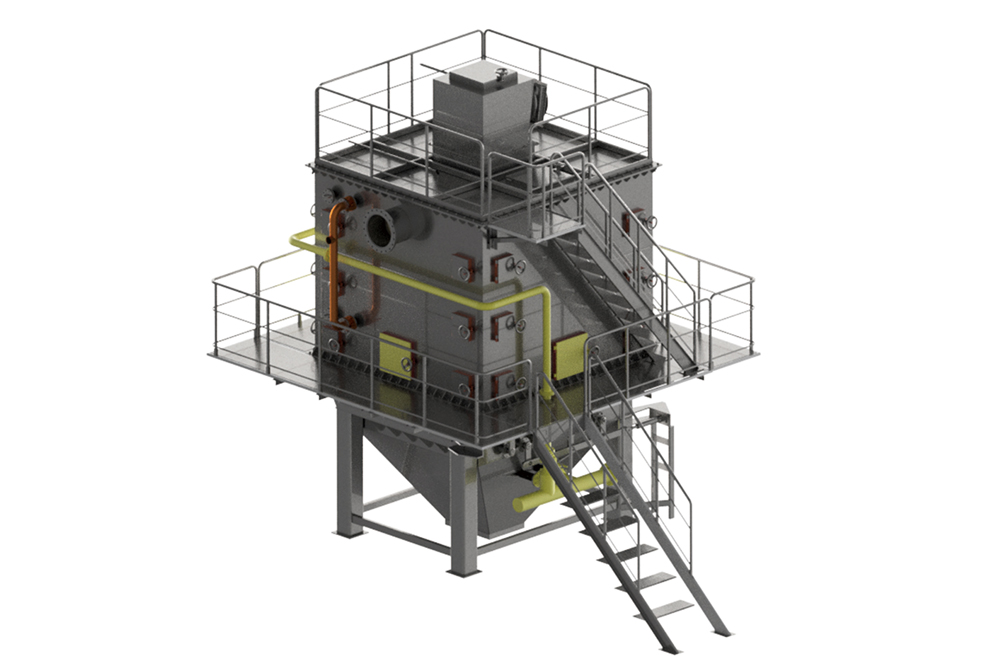

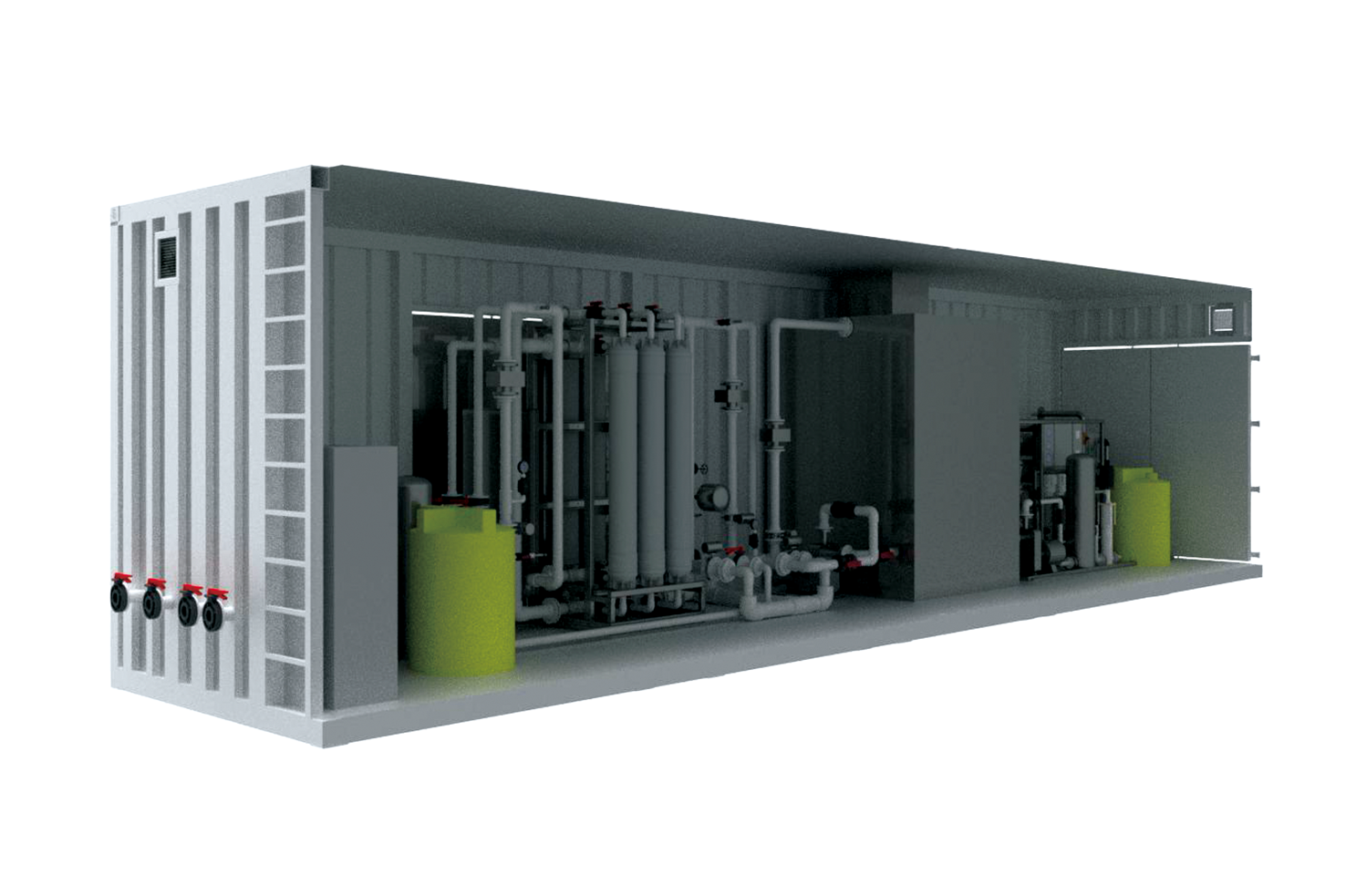

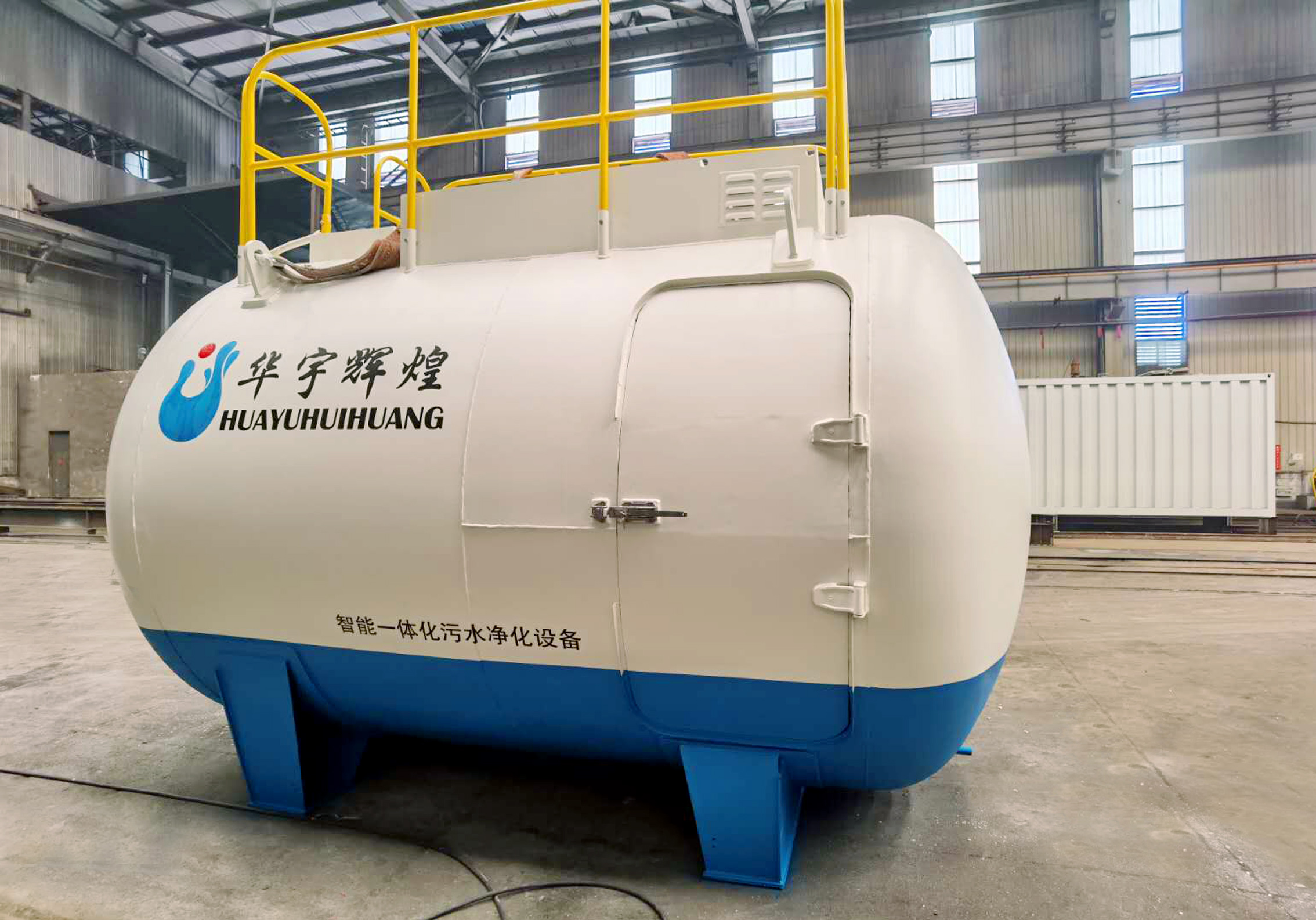

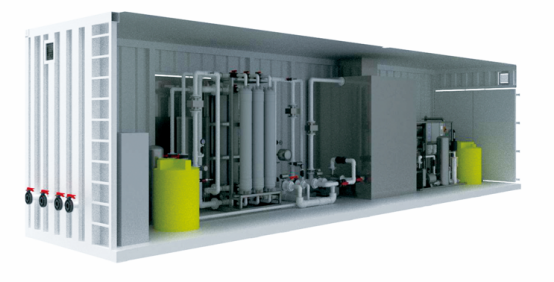

Equipment Structure and Appearance

Product Specifications

Model |

Scale (m3/d) |

Dimension L×W×H(m) |

Operating Power (kW) |

DW-3 |

3 |

5.0×2.0×3.5 |

3.5 |

DW-5 |

5 |

5.0×2.0×3.5 |

5.0 |

DW-10 |

10 |

14×3.0×3.5 |

8.0 |

DW-15 |

15 |

14×3.0×3.5 |

11.0 |

DW-20 |

20 |

15×3.0×3.5 |

18.0 |

Project Cases

AQUATIZ Brand Story

AQUATIZ is committed to optimizing drainage technology, optimizing drainage noise, optimizing bathroom floor height, optimizing spatial layout, optimizing clean bathroom, intelligentizing bathroom, and industrializing bathroom decoration. It leads and creates industry standards for bathroom technology and drainage...

READ MORE

R&D Strength

AQUATIZ is committed to optimizing drainage technology, optimizing drainage noise, optimizing bathroom floor height, optimizing spatial layout, optimizing clean bathroom, intelligentizing bathroom, and industrializing bathroom decoration. It leads and creates industry standards for bathroom technology and drainage...

READ MORE