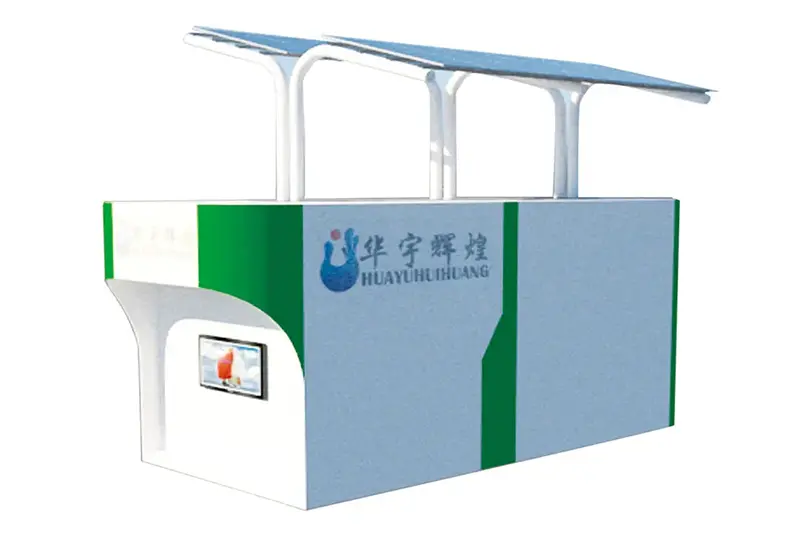

“Swift”Solar-Powered Sewage Treatment Bioreactor

Product Structure

(1)Microdynamics bacteria screen filter system

Innovative development of "Bacteria Screen Filter Layer"

Improved load capacity and nitrification capacity

Improved water quality

(2)Solar power supply system

Low equipment energy consumption is low

Dual power supply from solar energy and mains electricity

(3)Clear and turbid water identification system

Automatic identification, fully automatic gravity water production

Long regeneration period

Small footprint

(4)Intelligent control system

Automation of multi-mode operation

Equipment Features

①Microdynamics bacteria screen filter system

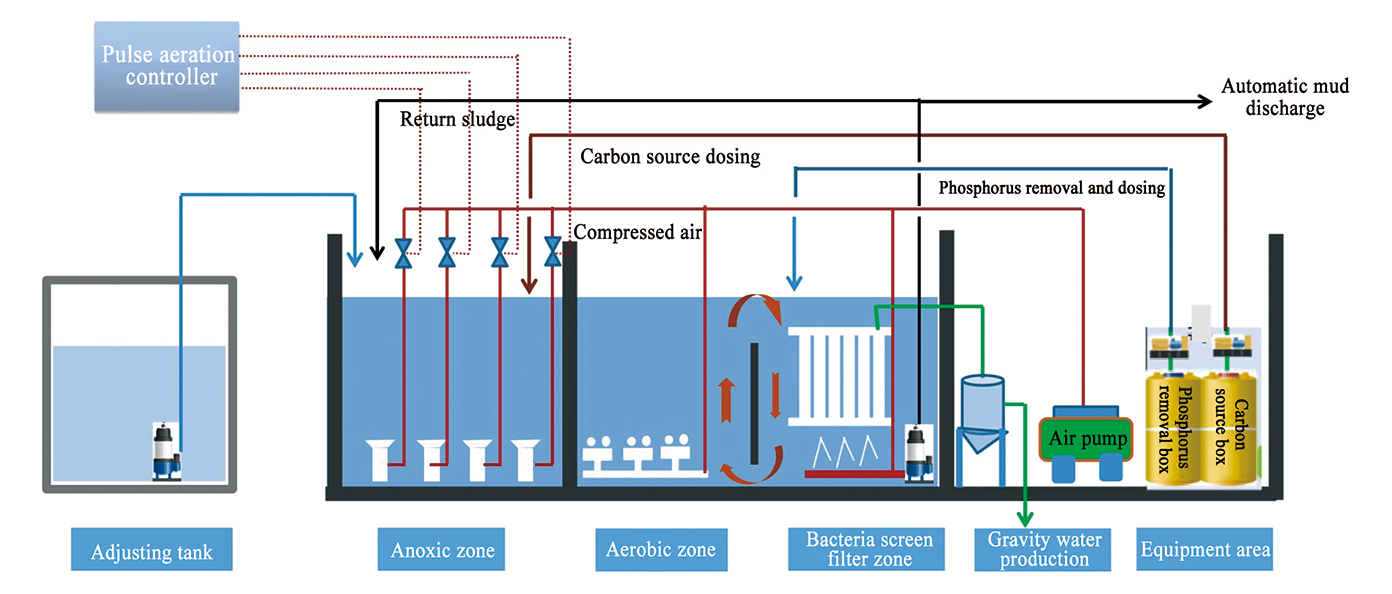

"Bacteria Sieve Filter Layer",a Innovatively developed dynamic biological filtration layer formed by microorganisms and their EPS on the surface of a special base membrane can achieve high-efficiency solid-liquid separation of mud and water is achieved through microgravity. The layer also has the advantages of zero energy consumption, excellent water quality, and improved system volume and system nitrification capacity.

②Clear and turbid water identification system

The system can automatically identify clear and turbid water and smartly controls the switching of the shunt electric ball valve to ensure the stability and quality of water production. The system enables automatic gravity water production, mud discharge, automatic water reuse irrigation, making operation and maintenance is relatively simple; long regeneration cycle (more than 30 days). And the flux can be restored only by high-intensity aeration without consuming chemicals; the process structure is compact and the floor space is small.

③Solar power supply system (dual power supply from solar energy and power grid)

Installed power: Energy consumption can reduce by more than 50% compared to MBR integrated equipment of the same scale;

Photovoltaic power supply: Green energy can be used to replace or as a supplement to the mains power. The dual power supply automatically switches to the optimal configuration, which can save more than 80% of mains power consumption.

④Intelligent control system

Automatic equipment control and multi-mode operation of the system are realized by configuring PLC, touchscreen and supporting control electrical components. Remote control modules can be matched according to different needs.

Process Flow

Product Advantages

Our equipment has obtained 6 invention patents and 1 utility model patent.

①Advanced technology

We utilize the microbial flora and EPS in activated sludge to form a nano-scale filtration membrane layer under the action of a special base membrane and hydraulic flow regime; thereby achieving efficient solid-liquid separation through microgravity without the need for sedimentation tanks and deep treatment. Effluent water reaches discharge standards.

②Energy efficient

Through process innovation and breakthroughs, the entire system is designed to be energy-saving. With very few power equipment, and the power is more than 50% lower than MBR equipment with the same processing scale.

③Solar powered

Equipped with standard solar panels and energy storage system, it can achieve 100% green energy power supply with less than 50 t/d, and the dual power switch of mains power and solar energy can realize millisecond-level automatic switching.

④Pulse aeration

The pulse aeration method is used for hydraulic mixing in the anoxic zone, which not only solves the fluidization effect of low dissolved oxygen sludge, but also solves the problem of high energy consumption and proneness to damage of traditional mixers.

⑤Simplicity and aesthetics

Simplicity and aesthetics appearance design concept, equipped with industrial LCD display, making the reactor smarter and simpler. The shape is combined with solar photovoltaic panels and looks like a flying swallow, hence the name "SWIFT".

⑥Intelligent remote control

The data generated by the equipment is collected into the PLC central control program through turbidity, flow meter, three-way valve, dissolved oxygen meter and other related sensors. The remote transmission and video image technology of the Internet of Things are used to realize remote transmission operation, monitoring and control. The operation of the reactor cam be completely visualized.

Product Specifications

Model |

Scale (m3/d) |

Dimension L×W×H(m) |

Power (kW) |

Installation method |

Power supply mode |

Voltage (V) |

SWIFT-10 |

10 |

2.8×2.0×2.5 |

0.6 |

Standard oveground type |

Solar energy ( main power supplement ) |

220 |

SWIFT-20 |

20 |

4.0×2.0×2.5 |

0.8 |

Standard oveground type |

Solar energy ( main power supplement ) |

220 |

SWIFT-30 |

30 |

4.4×2.0×3.1 |

0.9 |

Standard oveground type |

Solar energy ( main power supplement ) |

220 |

SWIFT-50 |

50 |

5.5×2.5×3.1 |

1.1 |

Standard oveground type |

Solar energy ( main power supplement ) |

220 |

SWIFT-100 |

100 |

8.5×3.0×3.1 |

2.0 |

Standard oveground type |

Solar energy ( main power supplement ) |

220 |

SWIFT-150 |

150 |

11.5×3.0×3.1 |

3.0 |

Standard oveground type |

Solar energy ( main power supplement ) |

220 |