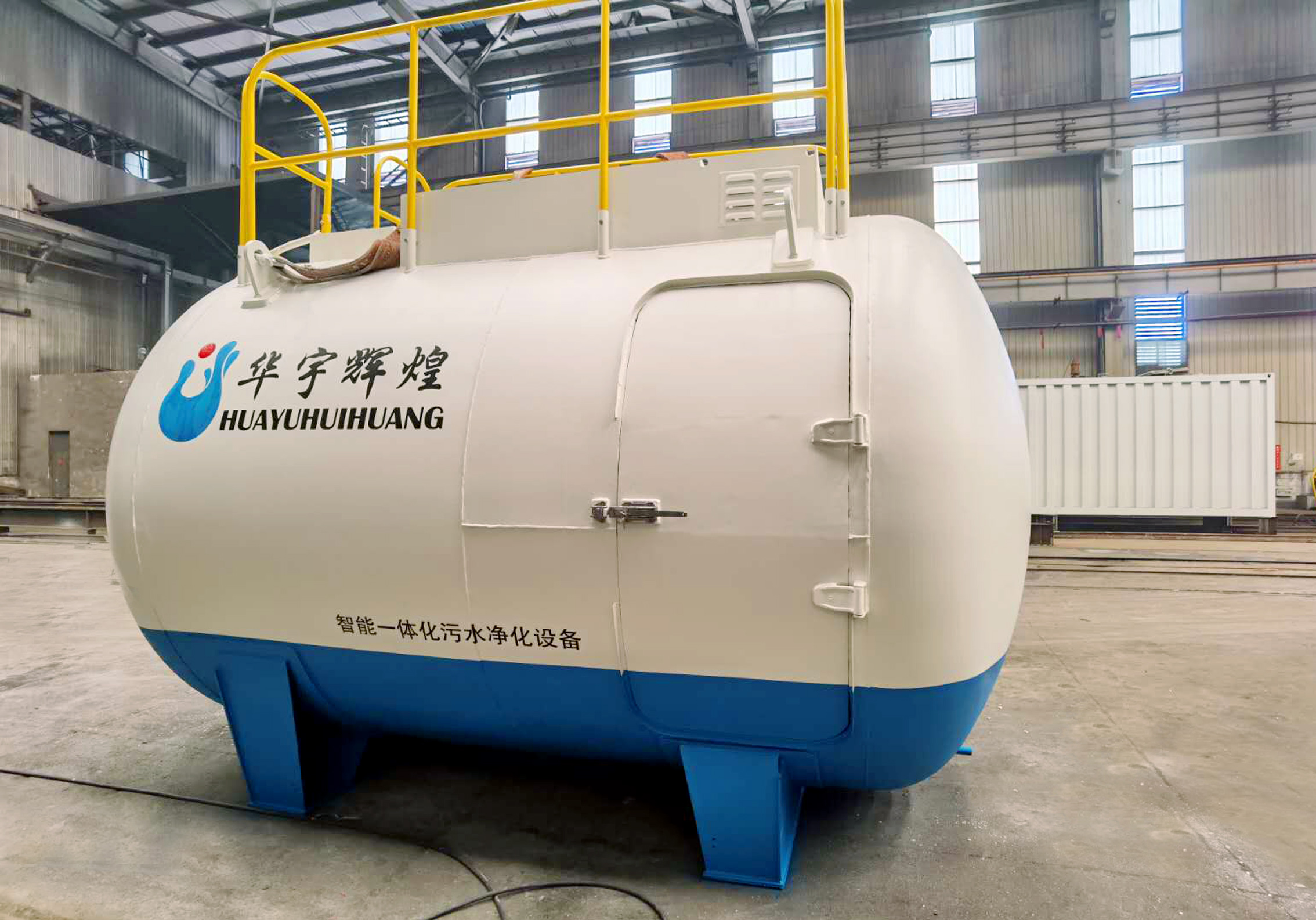

Manure Fertilizer Fermentation Tank

Equipment Features

Low Cost: The process consumes less energy and has low operating cost. Smaller foodprint (50 ~ 60 m²/unit).

High Automation: PLC is combined with upper machine to realize remote control.

Eco-friendly: Fully closed treatment does not produce secondary pollution.

Long Service Life: SUS304, material inside, corrosion resistance, long service life.

Process Flow

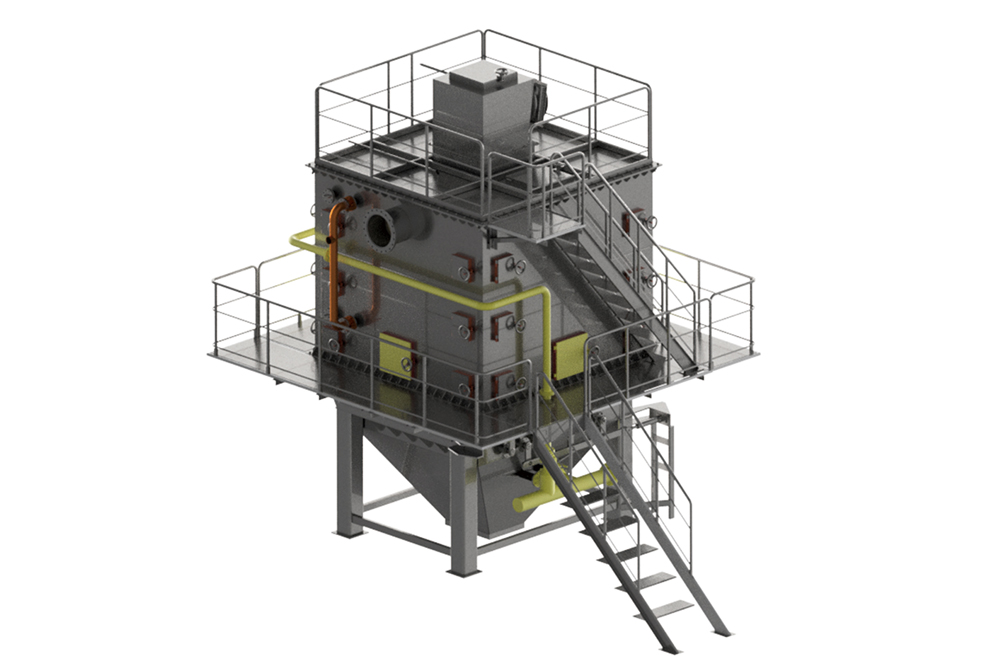

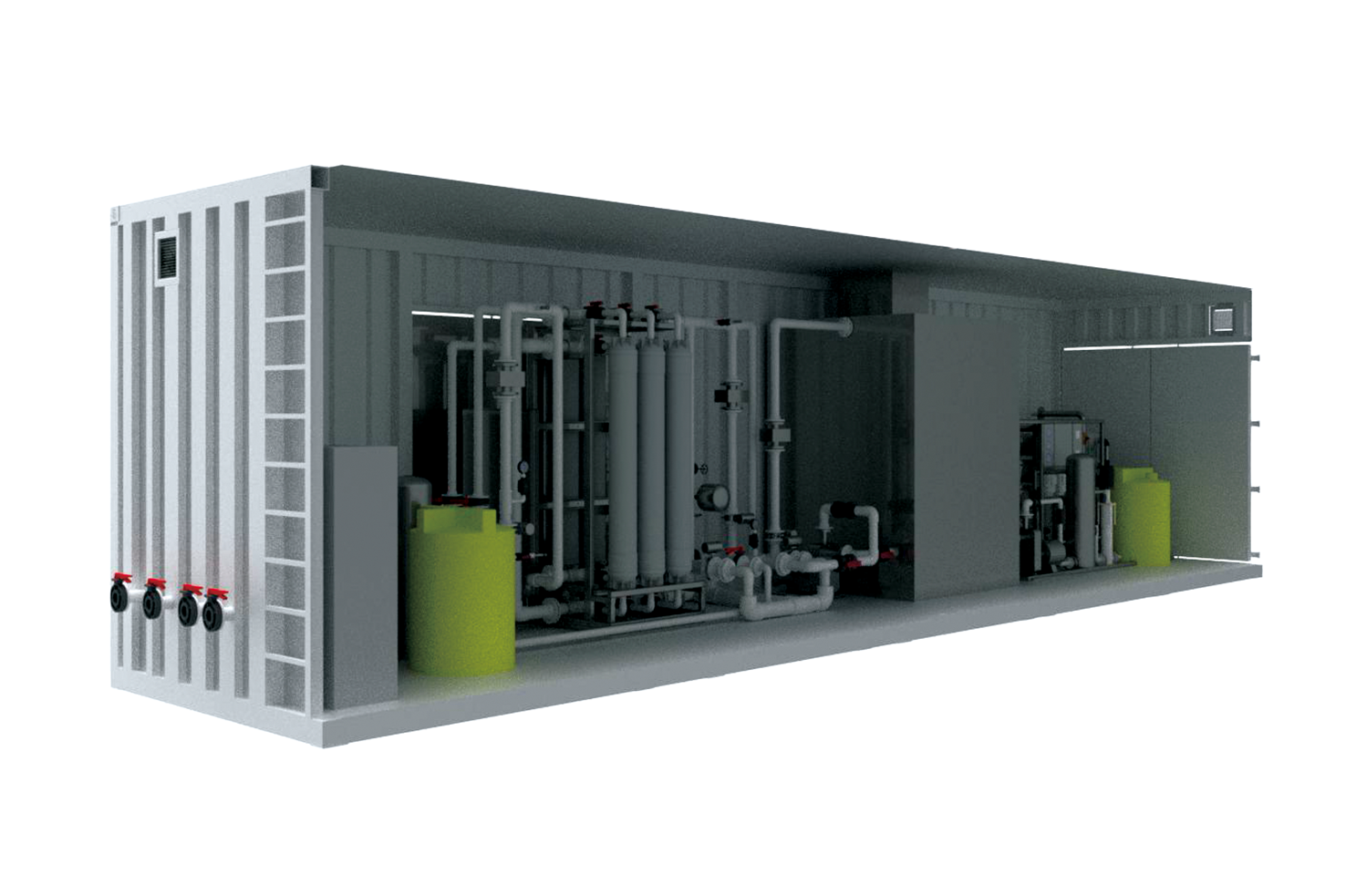

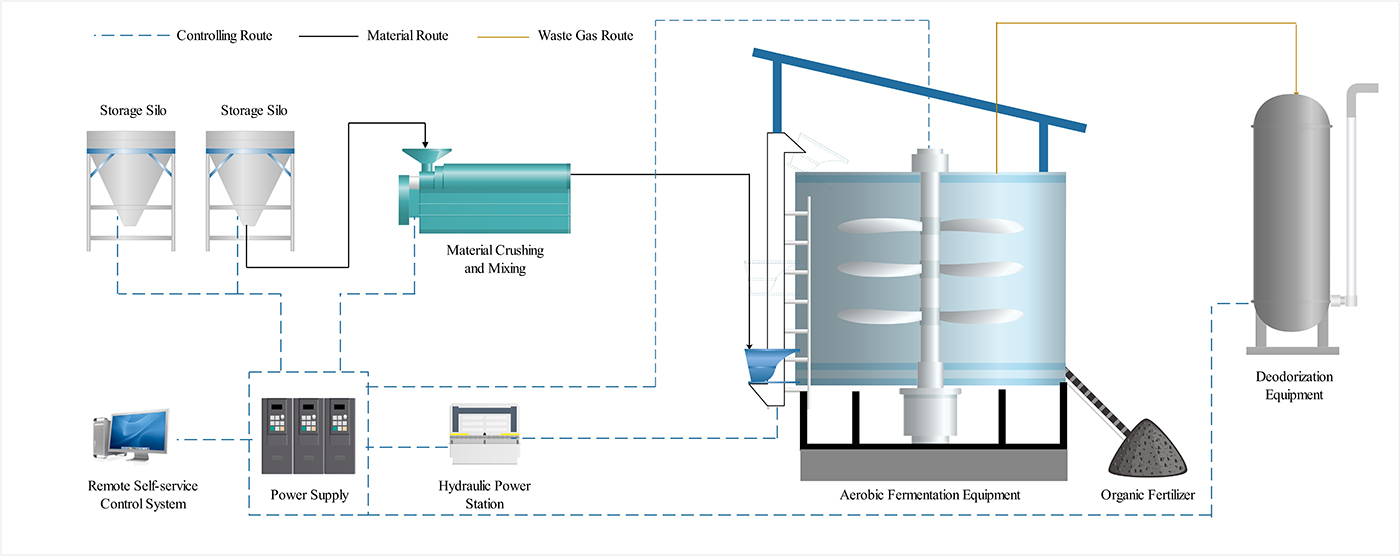

The equipment mainly includes the main body of aerobic fermentation equipment(upper, middle and lower) and waste gas treatment equipment.

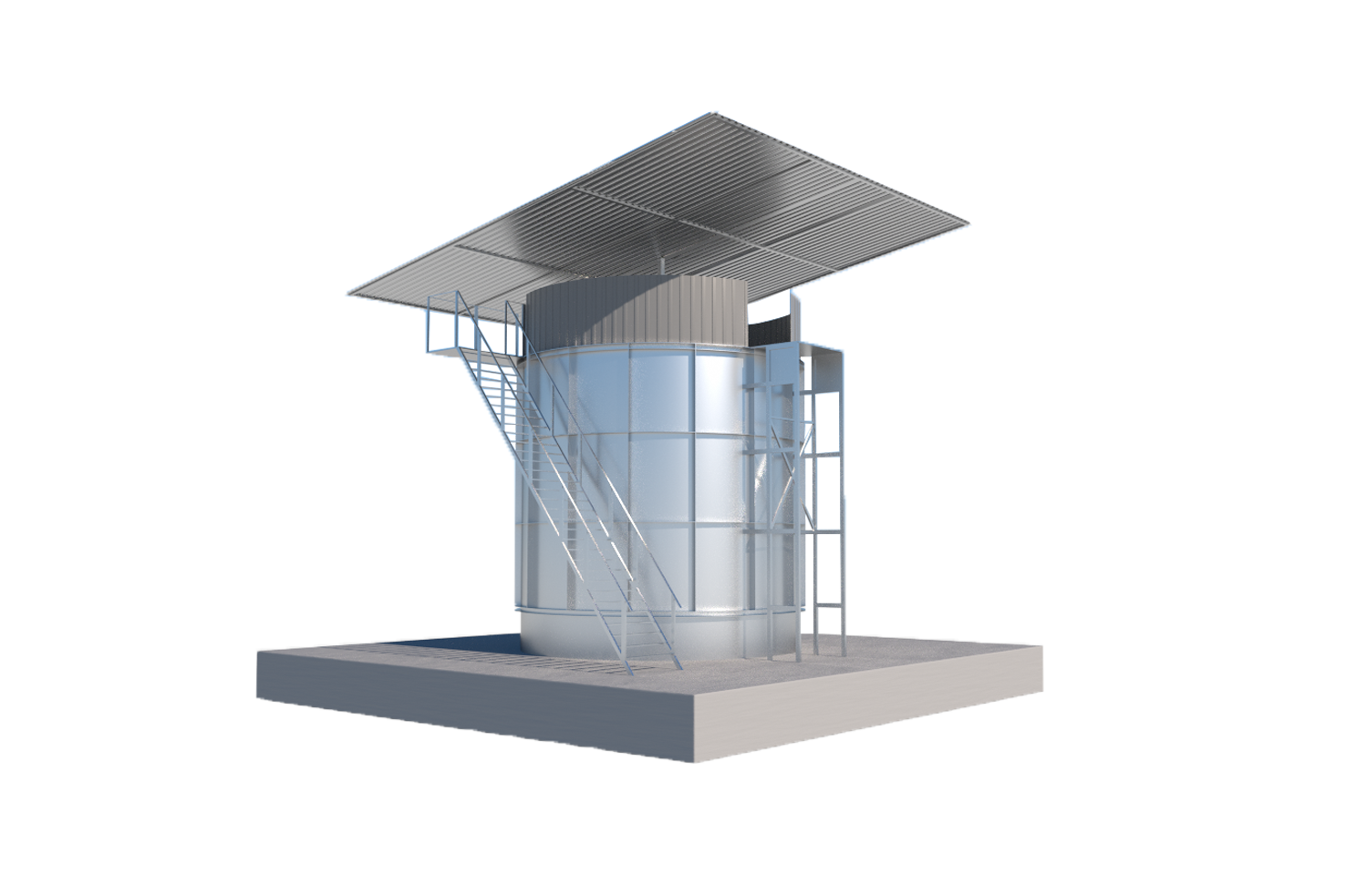

Aerobic Fermentation Equipment -- Upper: The upper part of the equipment mainly includes weather-shelter, maintenance platform, exhaust facilities, etc., to ensure the convenience of equipment maintenance.

Aerobic Fermentation Equipment -- Middle: The middle part of the equipment mainly includes automatic control system, fermentation tank, fertilizer export device, insulation layer, etc., to ensure that the materials in MFFT Manure Tank are in a better fermentation environment.

Aerobic Fermentation Equipment -- Lower: The lower part of the equipment mainly includes hydraulic station, fan, thrust hydraulic stirring shaft, etc., which is the power source of fermentation equipment operation.

Waste Gas Treatment Equipment --The deodorization system is mainly composed of exhaust gas collection pipeline and deodorization equipment to ensure that the gas meets the standard discharge and will not cause adverse effects on the surrounding atmospheric environment.

Aerobic Fermentation Equipment -- Upper: The upper part of the equipment mainly includes weather-shelter, maintenance platform, exhaust facilities, etc., to ensure the convenience of equipment maintenance.

Aerobic Fermentation Equipment -- Middle: The middle part of the equipment mainly includes automatic control system, fermentation tank, fertilizer export device, insulation layer, etc., to ensure that the materials in MFFT Manure Tank are in a better fermentation environment.

Aerobic Fermentation Equipment -- Lower: The lower part of the equipment mainly includes hydraulic station, fan, thrust hydraulic stirring shaft, etc., which is the power source of fermentation equipment operation.

Waste Gas Treatment Equipment --The deodorization system is mainly composed of exhaust gas collection pipeline and deodorization equipment to ensure that the gas meets the standard discharge and will not cause adverse effects on the surrounding atmospheric environment.

Product Specifications

Model |

Gross Power (kW) |

Total Weight (t) |

Tank Volume (m3) |

Handling Ability(m3/d) |

||

Pig Manure |

Cattle Manure |

Chicken Manure |

||||

MFFT-1T |

27.7 |

30 |

55 |

5 |

8 |

12 |

MFFT-3T |

38.2 |

36 |

80 |

4.5 |

7 |

9 |

MFFT-5T |

41.2 |

42 |

100 |

5 |

8 |

10 |

Environmental Standards

Wastewater: There is no waste water while operating.

Exhaust Gas: The purified exhaust gas meets the local emission standards.

Organic Fertilizer: Each index meets the relevant standards of local organic fertilizer and can be sold as organic fertilizer.