Convert Food Waste Into Compost Using The Kitchen Waste Composting Machine

1. Current status of kitchen waste disposal

The current state of food waste is a matter of urgent concern. In the United States alone, approximately 30-40% of the food supply is wasted, totaling more than 133 billion pounds of food annually. Beginning in 2022, SB 1383 requires every jurisdiction to provide organic waste collection services to all residents and businesses and to compost the collected organic waste. California's goal is to compost 75% of organics by 2025. The state estimates that will reduce greenhouse gases as much as taking a million cars off the road each year. Starting in 2024, SB 1383 states that residents who fail to recycle food waste may be subject to fines.

Most California residents buy small household garbage composters to process food waste. However, due to problems such as uneven composting and the production of a lot of odor, residents are still looking for other treatment methods to deal with food waste.

2. How does the kitchen waste composter convert kitchen waste into compost?

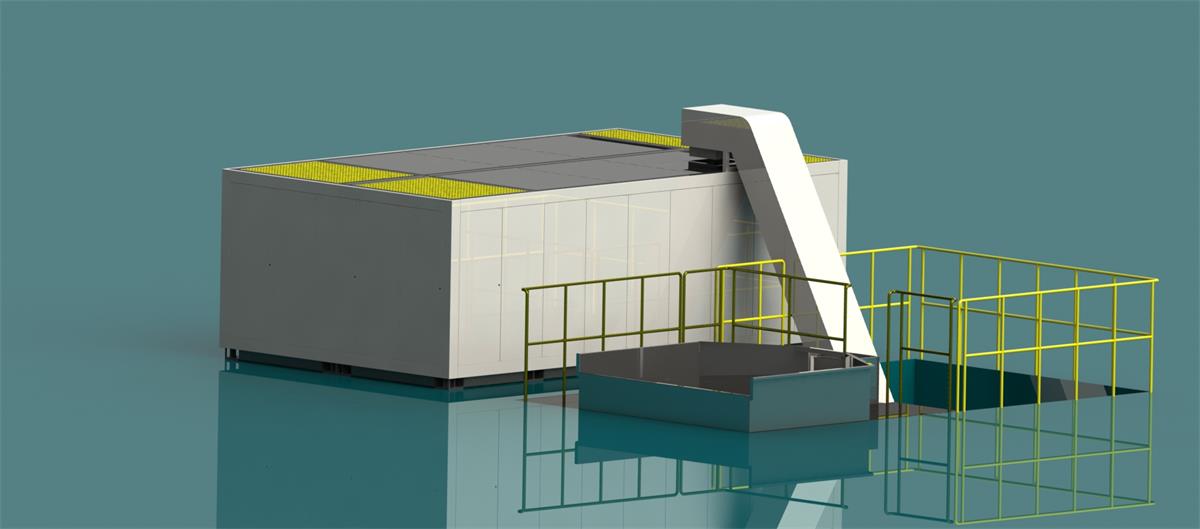

For areas such as communities, schools, factories, and islands, the collected food waste can be collected uniformly and processed using a kitchen waste composting machine. The mixed food waste has a more uniform texture and is of better quality than the fertilizer produced by a small household composter. In addition, compared with traditional composting technology, food waste composting machines occupy a smaller area, have shorter fermentation times, and have less flavor. They are one of the options available for food waste disposal at this stage.

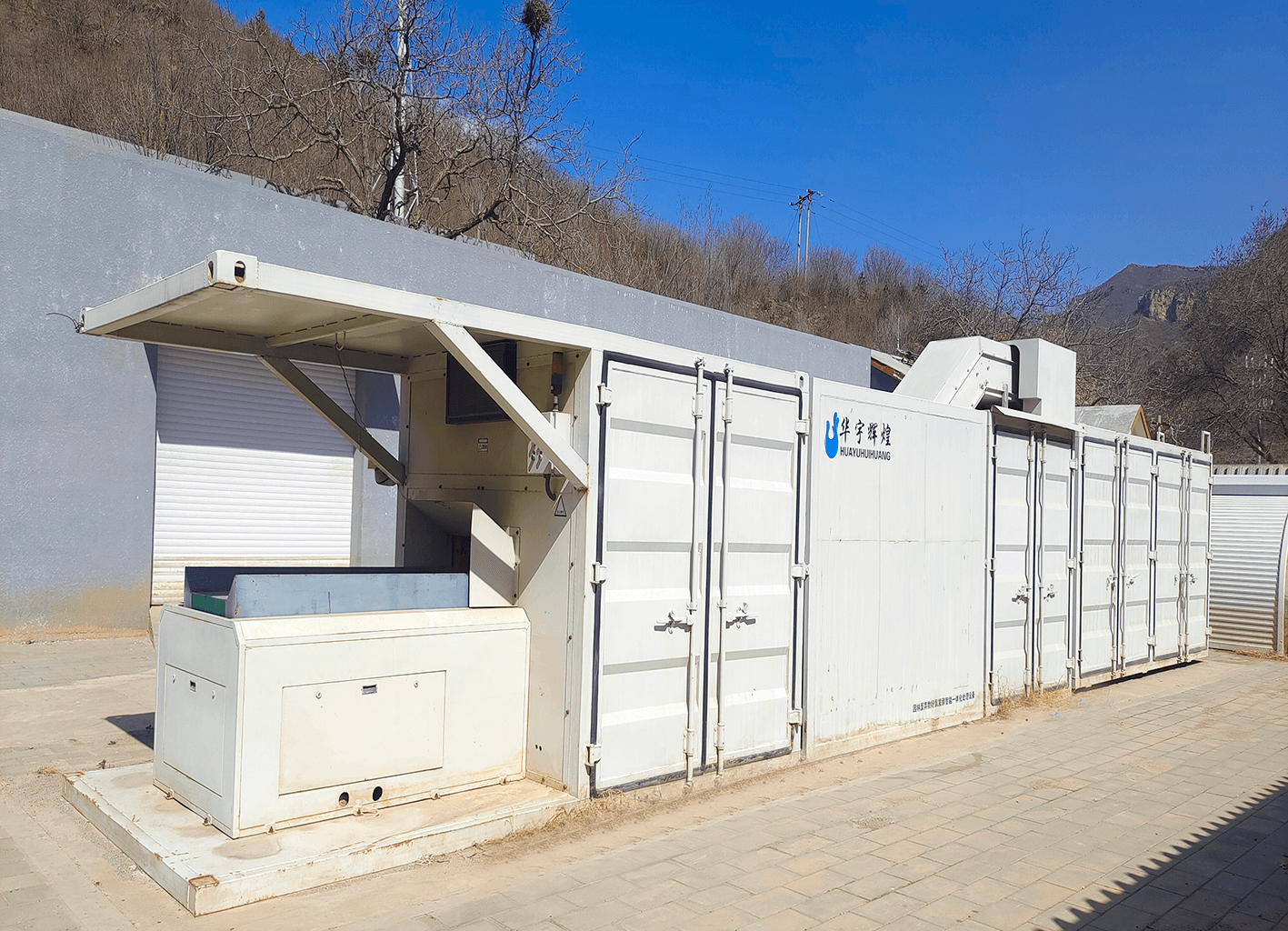

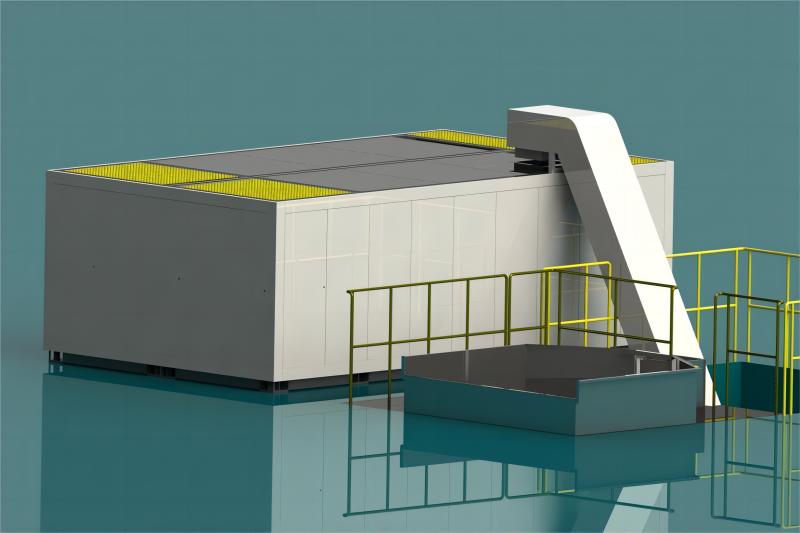

The OWC Food Waste Bio-Digester launched by HYHH uses high-temperature aerobic fermentation technology, integrating mixed material crushing, garbage weighing, rapid continuous fermentation, oil and water separation, built-in dustproof and deodorization, and PLC automatic control. This new kitchen waste composting machine can realize the resource utilization of food waste.

(1)Material receiving unit

Food waste is collected, transported to this processing station in 120L or 240L special buckets, and placed in designated locations.

(2) Food waste treatment equipment

The garbage is dumped to the sorting platform via the elevator, and plastics, ironware, glass, etc. that cannot be fermented are manually sorted out, and then enter the crusher for crushing. The crushed garbage enters the solid-liquid separator after being sprayed and washed with water. The separated solids undergo high-temperature aerobic fermentation for 24 hours to produce nutrient soil or humus. The grease separated from the liquid can be recycled by qualified companies, and the water will be discharged into the municipal pipe network after preliminary treatment.

The food waste treatment equipment itself is equipped with gas collection and treatment devices. This can remove the odor generated during the process to improve the operating environment of the equipment and protect the occupational health of operators.

(3) Aging unit

The materials processed by the food waste treatment equipment are sent to the aging warehouse to further decompose the easily decomposed and difficult-to-decompose organic matter that has not been decomposed in the main fermentation process to obtain a fully mature organic fertilizer product.

(4) Deodorizing unit

Because odorous gases can easily be produced during food waste treatment, causing sensory discomfort, deodorization equipment can be installed in food waste treatment plants to avoid secondary pollution to the environment.

3. OWC Food Waste Bio-Dgester process characteristics

(1) High degree of integration, compact process layout, small footprint, and convenient transportation;

(2) The device has a modular structure and is easy to install;

(3) Agricultural and forestry waste treatment equipment, universal indoor and outdoor model design, wide range of use;

(4) PLC automatic control, no need for special personnel on duty, low operating cost;

(5) Built-in deodorization system to avoid secondary pollution caused by odor generated during the fermentation process.