The Key Functions of Waste Incinerator

Waste incinerators are environmentally friendly facilities that converts combustible garbage into CO2 and H2O at high temperatures. Incinerators can process domestic waste, municipal waste, medical waste, etc. Incinerators reduce the volume of waste during the incineration process and recover heat for heating and power generation.

Developed cities and regions usually build large-scale waste incineration plants of around 1,000 tons, and use mechanical grate furnaces to incinerate sorted Municipal Solid Waste uniformly to generate electricity. However, this centralized incineration treatment method is not suitable for remote, small-populated towns,villages, islands, expressway service areas, and other areas where the total amount of garbage is small and transportation costs are high.

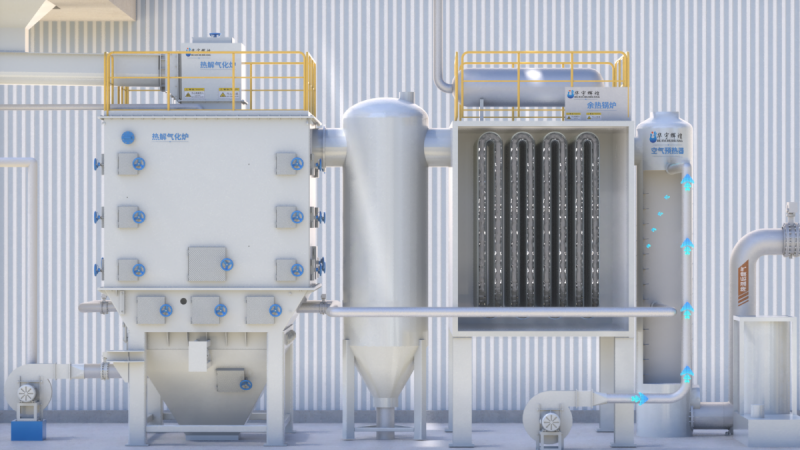

HYHH designed the High Temperature Pyrolysis Waste Incinerator (HTP Waste Incinerator) for this type of decentralized point source domestic waste treatment. This HTP Waste Incinerator uses pyrolysis gasification technology to break the chemical bonds of organic components in garbage using thermal energy under anaerobic or anoxic conditions to generate small molecule combustible gases, liquid fuels, and coke. The core incinerator adopts a structure of double-chamber. The combustible substances produced from the first combustion chamber enter the second combustion chamber for oxygen combustion. The reaction temperature is 850~1100℃, which avoids the generation of dioxin and low ash and slag production. Compared with mechanical grate furnaces, the structure of HTP Waste Incinerator can better ensure the stable operation of the system under small processing volumes.

The Key Functions of HTP Waste Incinerators

(1) Strong Inclusiveness

① Suitable for processing various materials such as rubber and plastic, paper, knitted fabrics, and plastics.

② After the materials are pretreated, the volume of waste can be reduced and the properties of the materials can be balanced. This can avoid fluctuations in waste characteristics that may affect actual operations.

(2) Good Pyrolysis Effect and High Weight Reduction Rate

① The multi-layer structure of the incinerator wall ensures the heat insulation and heat storage effect. The double-chamber can realize the heat complementation of the first and second combustion chambers, and no auxiliary fuel is needed for normal operation (except for starting the furnace).

② 90% garbage mass reduction rate, and 95% volume reduction rate, achieving the maximum reduction of garbage.

(3) Waste Heat Utilization and Environmental Protection

① Set up a heat exchanger to realize heat exchange between water and flue gas. The hot water after heat exchange can be used as heating water in winter.

② Selecting a heat exchanger with a large contact area can achieve rapid cooling of the flue gas. The temperature can be reduced to 180~240℃ within 2 seconds, effectively avoiding the regeneration temperature of dioxin (250~400℃, 300℃ is the best Significantly), reducing the regeneration of dioxin.

(4) High System Automation and Visualization

① The central control room can realize the start and stop of most equipment, automatic water replenishment, and dosing of equipment.

② A pressure transmitter is installed in the pyrolysis incinerator and interlocked with the fan to realize automatic control of air volume.

③ Equipped with instruments such as temperature, pressure, oxygen content, and pH meter, which can control the combustion situation in the furnace and the operation status of the flue gas system in real-time, and realize the visual operation of the system.

(5) Low Failure Rate and Long Equipment Service Life

① The main components in the incinerator are made of special materials with a temperature resistance of 1000°C and are lined with thermal insulation and heat-resistant layers. Ensure the equipment's high temperature resistance, wear resistance, and corrosion resistance to extend its life.

② Design a temperature protection mechanism for key nodes of the equipment to avoid equipment damage caused by too high or too low temperatures.