Agricultural And Forestry Waste Treatment

2024-04-16 16:16:41

What are the wastes from forestry and agriculture?

Agricultural and forestry waste mainly refers to organic materials discarded during the entire agricultural and forestry production process. First, agricultural and forestry waste such as straw, rice husk, bagasse, and forest waste. Second, feces are produced during livestock and poultry breeding. Third, unused fertilizers, pesticides and related containers in agricultural and forestry operations.

The main components of straw agricultural and forestry waste are cellulose, hemicellulose and lignin. Among them, C, H, and O elements account for 65% to 90%, and are rich in N, P, K, Ca, Mg, Zn, S and other elements. Since this type of waste output is related to local crops, it has the characteristics of large seasonal output for countries and regions dominated by agriculture. The traditional treatment method is on-site incineration. This treatment method has a low energy utilization rate and the black smoke produced by combustion seriously pollutes the ecological environment.

What happens with agricultural waste?

Agricultural wastes may be used as a source of energy, bedding, mulch, organic matter, or plant nutrients. Properly treated, they can be marketable. Common agricultural and forestry waste treatment technologies include the following:

(1) Fertilizer: Straw is rich in organic matter and N, P, K, C and other elements. After proper treatment, it can be returned to the field as fertilizer to increase nutrients in the soil. The common practice is to return it directly to the field after crushing, and mix it directly with the soil during farming, using microorganisms in the soil to decompose and decompose it. Or it can be piled and fermented, and then applied to the land after it is mature.

(2) Feed conversion: Some agricultural and forestry wastes, such as soybean straw, rape straw, peanut stalks, etc., have low lignification degree and relatively high nutrition, and can be fed as feed to cattle, sheep and other herbivorous animals.

(3) Energy conversion: Use biological fermentation technology, thermal decomposition technology, compression and solidification technology, etc. to convert agricultural and forestry waste into energy products such as biogas, combustible gas or pellet fuel.

(4) Matrixing: Agricultural and forestry wastes are processed and used as breeding litter, or crushed and used as culture substrates for fungi.

(5) Industrial raw materials: Using agricultural and forestry wastes as raw materials for activated carbon, pulp, degradable plastics, building materials, etc. can reduce the felling and use of wood. Straws can also be used to make handicrafts such as straw ropes and straw mats to increase local income.

Aerobic fermentation of agricultural and forestry wastes

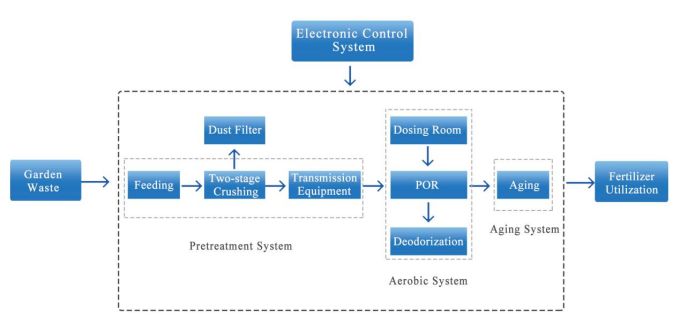

In the fertilizer technology of agricultural and forestry waste, the broken straw and branches are directly returned to the fields, and the pathogens and insect eggs they carry will enter the farmland and harm the growth of crops. Traditional compost takes a long time to ferment, occupies a large area, and has an unpleasant smell. On this basis, HYHH optimized and developed the Agricultural Waste Disposal Equipment (AWD) integrated complete set of environmental protection equipment based on the characteristics of agricultural and forestry waste.

This equipment mainly uses aerobic fermentation technology, that is, under the condition of a sufficient supply of oxygen, organic solid waste generates higher temperatures under the action of aerobic microorganisms, causing organic matter to biodegrade and become harmless, and ultimately generating stable humification products. In addition, the equipment is also equipped with a pretreatment and crushing system to make the fermentation raw materials more uniform; an intelligent control system is easy to operate and can effectively control the fermentation status and provide real-time online feedback. In addition, a deodorization system can be equipped according to the processing conditions to ensure the working environment of the operators.