Introducing the Manure Fermenter – an innovative solution for converting livestock manure into organic fertilizer. Also known as an aerobic fermenter and manure composter, this state-of-the-art equipment harnesses the power of microbial activity to efficiently biodegrade the organic matter in manure. converting it into organic fertilizer, which can be used for soil improvement and landscaping. The aerobic fermentation process can gradually convert manure into organic fertilizer, which can be used for soil improvement and landscaping, while effectively solving the challenges of livestock manure management.

1.What are fermentation tanks used for?

As a typical biomass, livestock and poultry manure is rich in a variety of organic matter and nutrients, including nitrogen (N), phosphorus (P), potassium (K), calcium (Ca), and other nutrients required by 13 types of plants. However, if livestock and poultry manure is directly applied, excessively rich nutrients entering the water body can easily cause eutrophication and pollute the water environment. Moreover, the presence of a large number of insect eggs and pathogens in untreated feces will harm the growth of crops. In addition, livestock and poultry manure stored for a long time or composted in the open air will produce stench and take a long time to mature.

The fermentation tank uses aerobic fermentation technology to achieve harmless treatment and resource utilization of livestock and poultry manure. After simple crushing, the livestock and poultry manure enters the fermentation tank. The stirring system in the fermentation tank mixes feces and microorganisms evenly, which is beneficial to the rapid decomposition of organic matter. The integrated intelligent control system of the fermentation tank can accurately control the fermentation temperature and oxygen content in the tank to ensure the stable operation of the equipment. At the same time, the equipment is equipped with a deodorization system to ensure that operators are always in a good working environment and reduce environmental pollution.

2.How do you ferment manure?

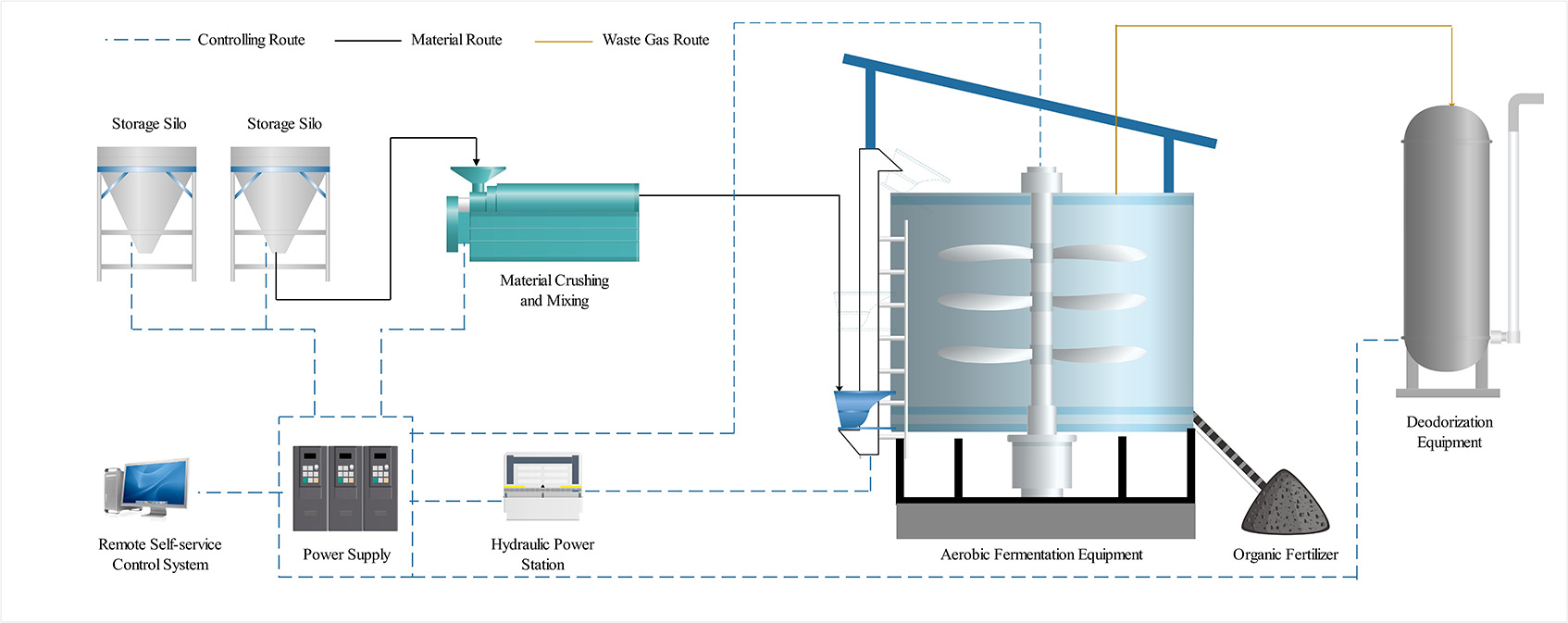

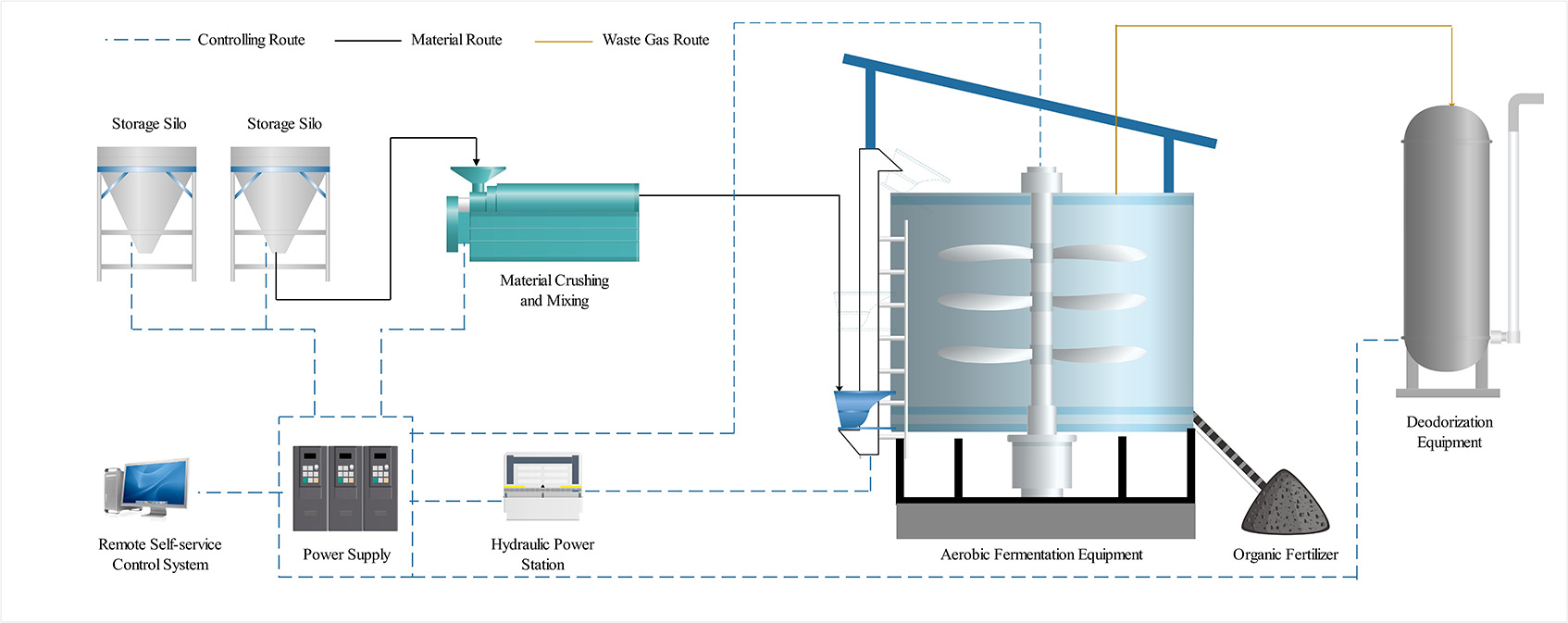

The equipment mainly includes the main body of aerobic fermentation equipment(upper, middle and lower) and waste gas treatment equipment.

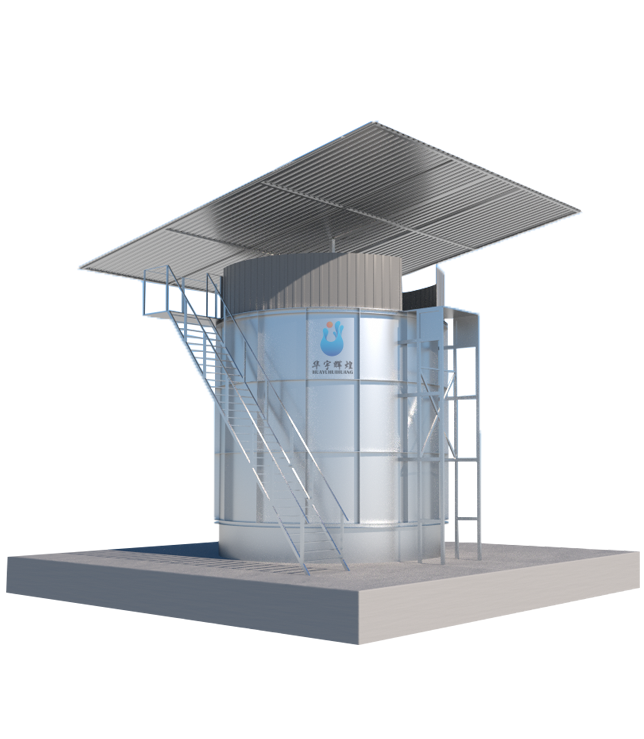

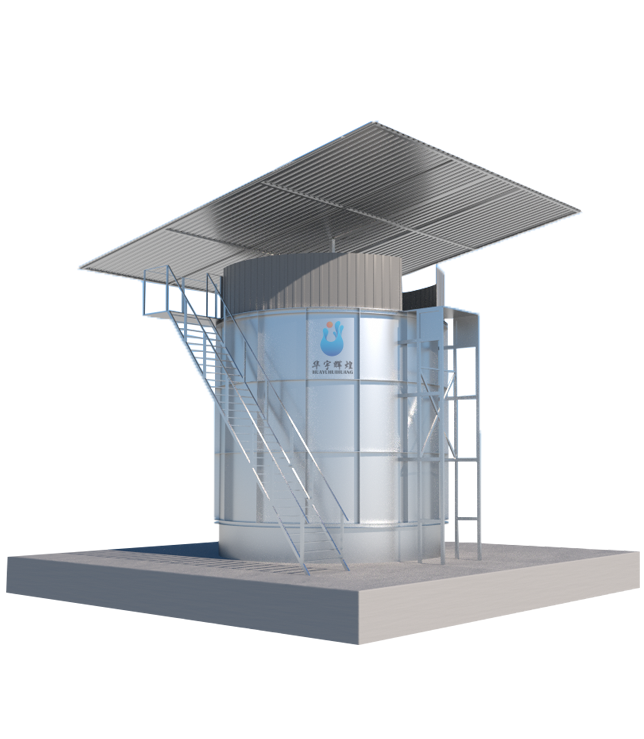

Aerobic Fermentation Equipment -- Upper: The upper part of the equipment mainly includes weather-shelter, maintenance platform, exhaust facilities, etc., to ensure the convenience of equipment maintenance.

Aerobic Fermentation Equipment -- Middle: The middle part of the equipment mainly includes automatic control system, fermentation tank, fertilizer export device, insulation layer, etc., to ensure that the materials in MFFT Manure Tank are in a better fermentation environment.

Aerobic Fermentation Equipment -- Lower: The lower part of the equipment mainly includes hydraulic station, fan, thrust hydraulic stirring shaft, etc., which is the power source of fermentation equipment operation.

Waste Gas Treatment Equipment: The deodorization system is mainly composed of exhaust gas collection pipeline and deodorization equipment to ensure that the gas meets the standard discharge and will not cause adverse effects on the surrounding atmospheric environment.

3.What are the benefits of fermented organic manure?

The fermentation tank produces organic fertilizer substrate after treatment, which can be used to make soil conditioners and organic fertilizers to increase the nutrient content of the soil.

One of the most significant advantages of utilizing organic fertilizer substrates produced in fermenters is the reduction in the use of chemical fertilizers. By incorporating organic alternatives into agricultural practices, farmers can minimize their reliance on synthetic chemicals, thereby reducing environmental impact and potential harm to ecosystems.

Furthermore, the use of organic fertilizer substrates contributes to the development of sustainable agriculture. By using nutrient-rich natural materials to enrich your soil, you reduce the need for expensive and potentially harmful agricultural inputs. This in turn promotes a more balanced and sustainable approach to agriculture, benefiting the environment and the long-term viability of agricultural practices.

4. Equipment features of HYHH’s Manure Fertilizer Fermentation Tank

Low Cost: The process consumes less energy and has low operating cost. Smaller foodprint (50 ~ 60 m2/unit). High Automation: PLC is combined with upper machine to realize remote control.

Eco-friendly: Fully closed treatment does not produce secondary pollution.

Long Service Life: SUS304 material inside, corrosion resistance, long service life.